When designing a country house or giving in advance, one should think about how comfortable temperature conditions in all rooms are in all rooms, that is, to provide equipment of the heating system. Conventional ovens gradually go into the past, they are displaced by steam boilers, designed for more economical for this locality fuel. In order to reasonably, with minimal losses, use the bought fuel, it is necessary to arma with some knowledge of the device for heating devices and the effect on the efficiency of heat transfer area of the boiler heating, regardless of the type of fuel used in them.

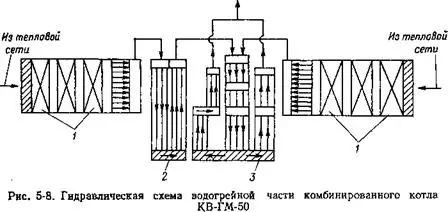

Scheme of heating boilers.

To do this, you will have to consider, due to which in steam boilers, the process of obtaining a steam leading to the heat of hot water in the heating system when it is properly calculated and mounted.

What is considered to be the surfaces of the heating of the boilers?

The system located directly in the boiler housing, above the furnace and on its parties and is, in most cases, the design of metal tubes, which passes the coolant (water), is the main working area of steam boilers. The outer surface area of the tubes washed by hot gases is the surface of the heating of steam boilers.

The greater the total heated surface, the more effective the heat carrier (water) is heated to the required temperature in steam boilers.

Scheme of heating surface of the boiler.

The name of this system is more familiar - the heat exchanger, since it is due to its device that the heat is carried out direct transmission from burning fuel to water.

Why are the surfaces, not the volume of water in the heat exchanger of steam boilers? With a sufficient temperature of the burning of fuel 1 liters of water, the boiling point will reach faster, if he is heated not in one vessel, but in several, around the walls of each of which are hot gases. Thus, the volume of the coolant, divided into narrower flows, due to the fact that the structures use the pipes of a small diameter, it warms up faster, which significantly increases the efficiency of the boiler and contributes to economical fuel consumption. In addition, small-diameter pipes can be used with a fairly significant increase in pressure, which can be achieved in steam boilers.

Article on the topic: Pompona from Tulle do it yourself

In steam boilers, as a heat exchanger separating water (coolant) and the heating of its gases and at the same time, almost without losses passing through the walls of metal tubes heat from the furnace to water, small diameter pipes are used. These pipes are made of cast iron, steel, stainless steel or copper. Materials are given in ascending order of value and relative increase in the service life of the boiler, with the exception of the first two positions (pig-iron pipes are more durable, but more fragile, fear of shocks, and steel pipes are afraid of corrosion).

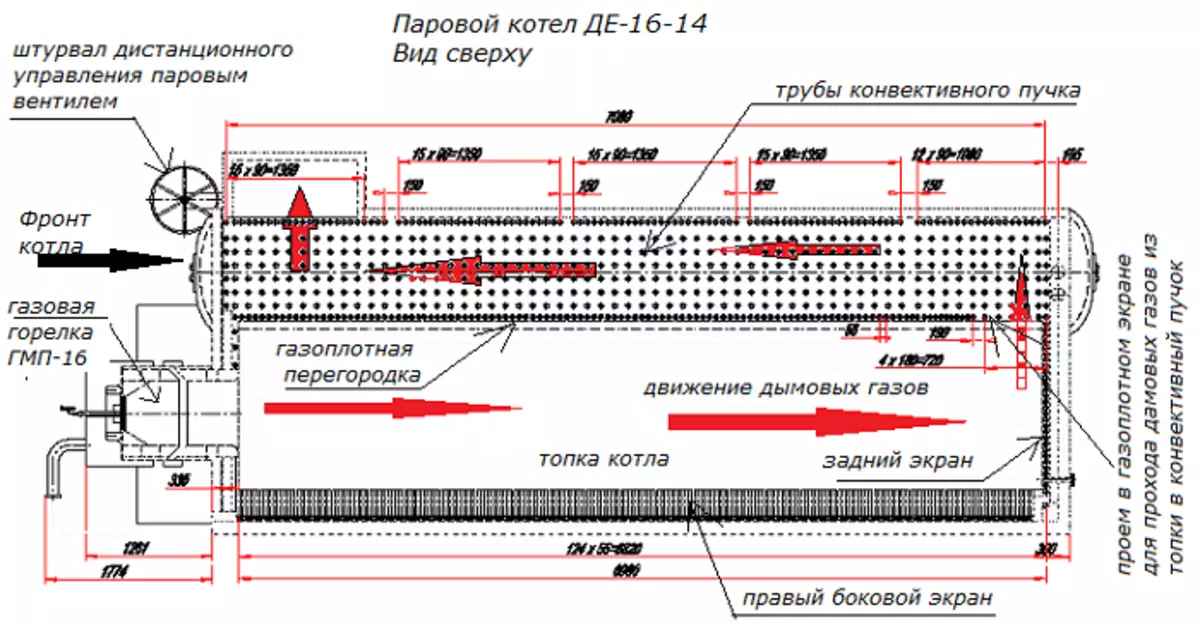

Convective and screen heating surfaces

The diagram of heating the convective surface of the boiler.

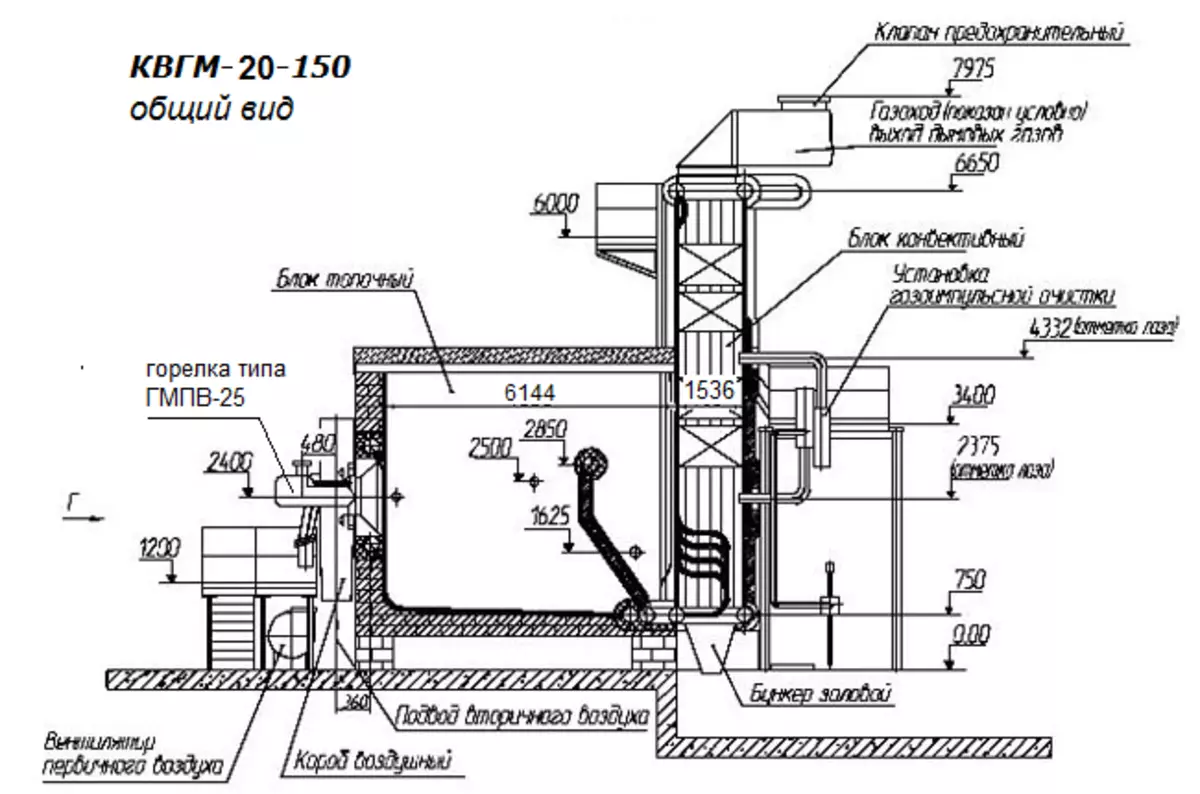

The most common in low-power boilers the design of the heat exchanger, when the vaporization is due to hot gases, rising up and warming water. Located above the furnace of the system of the tubes (in the simplest structures of steam boilers, it is a solid capacity) are a convective (refrigerated) surface of heating.

The on-screen heating surfaces get heat directly in the furnace, located in its right, left and rear. Their heating occurs due to thermal radiation during fuel burning. For the manufacture of the on-screen surfaces of heating boilers, as well as convective, cast iron, steel or copper (almost eternal) pipes are used.

In homemade boilers (the basic principles of their manufacturer are shown below) The screen surfaces of the heating are presented by a side of the tank or heat exchanger in the form of a tank located in the fireproof zone, since, in addition to the ascending flows of preheated air, its heating is provided by the heat radiation of the heating itself, the temperature in which can reach several hundred degrees.

The diagram of heating the on-screen surface of the boiler.

In boilers on solid or liquid fuel, as well as in the combined, heating surfaces, both on-screen and convective, and convection, can be subjected to ash sediments, which reduces the efficiency of the boiler. The heating surfaces in solid fuel steam boilers requires greater attention during operation. Since these surfaces make up the pipes, it is very important to ensure that there are free hot air flows between them.

Article on the topic: Rolled Curtains Day-Night: Recommendations and Tips

When choosing a boiler, attention should be paid at that time that in the passport characteristics to individual types of boilers, the level of heating surface is given, but the volume of heat exchanger in liters. It remains to trust the manufacturer who had to be literately distributed in the passport to the passport in the tubes and side screens (where they are). Only conventionally can agree that there is direct dependence between the total area of the surface of the boiler heating and the heat exchanger.

Industrial boilers have heating surfaces from 25 square meters, domestic - significantly smaller, for example, 18 kW boilers have the surface area of heating a little more than one square meter, which makes it possible to provide a warm house with an area of about 100 square meters.

Some principles of homemade boiler facilities

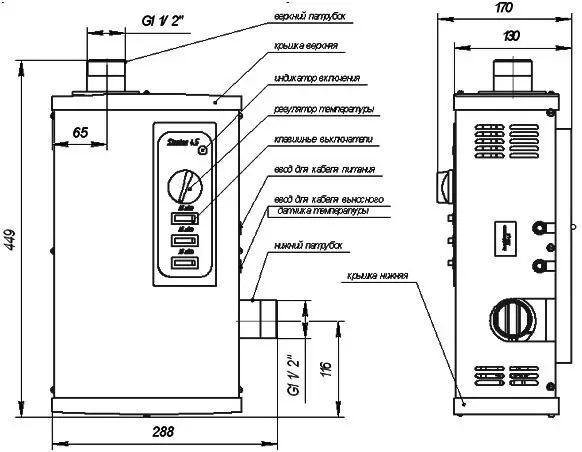

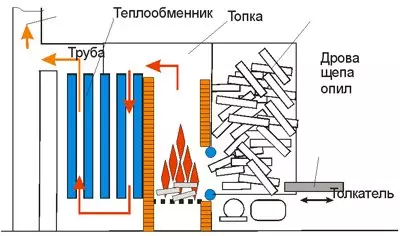

The scheme of the homemade heating boiler.

Using theoretical knowledge of the effect of the area of heating surfaces on the efficiency of the boiler, it is possible to achieve the maximum possible heat transfer and when the heating boiler is combined with an existing oven for the device for steam heating in the house.

The simplest boiler for heating or supplying hot water, built on the basis of the stove, can be made in two ways: mounting the body of the boiler around the chimney or install the heat exchanger directly over (or for) the combustion compartment. It is easier to implement the first option - the construction of a cylindrical reservoir above the furnace with the chimney passed through its central part. Of course, in this case, a part of the chimney, discharged from the furnace combustion products, needs to be made of a cast iron or steel (with a thick wall) of the pipe. That is, the re-equipment of the bourgearies to the boiler, "sitting" on her pipe, is quite feasible.

In the second case, directly in the furnace is located under the heat exchanger. Theoretically achieve maximum heat transfer to heat the water for the heating system, if you place the heat exchanger tank in such a way that the ascending hot streams are washed from all sides, but for this you have to reconstruct the stove. It is not bad if it is not a cube welded from metal sheets, but a kind of construction from pipe segments: the heating system is heated much less time.

Article on the topic: Features of the device for toilet bowl and its installation

In addition to the location of the pipe or cube above the furnace, some of them can be placed on the side walls of the furnace, thus organizing on-screen surfaces that will enhance the efficiency of the system.