So that in the apartment or house there is fresh and clean air, there should be very good ventilation in the kitchen. With the task of timely removal of odors when cooking, natural ventilation does not cope, because a special forced ventilation device hang over the slab - a kitchen hood. How to set the hood right how to fix it and display the ventilation system - about it next.

Install the hood in the kitchen - a wise decision

How to hang hood over the stove

With a properly selected amount, it is equal in width or even a little more plate width. To properly install the hood, you must properly place it and secure. There is a tilt exactly above the stove. The installation height depends on the type of cooking surface:

- Over the gas stove, the minimum allowable exhaust hanging height is 75 cm.

- Over electrical significance is slightly less - 65 cm minimum.

We determine the accurate height on your own - by the growth of the hostess, which will prepare. The lower edge of the hood should be slightly above her head. The lower than the minimum distance should not be hung, and above can be. But if you need to hang equipment higher than 90 cm from the plate level, an extra-power unit is needed - so that the polluted air is deleted efficiently.

Minimum height for installing exhausts above the gas and electric stove

The extract is attached depending on the type. Built-in - to a specially ordered closet size. Hinged (flat) and dome (fireplaces) - to the wall. Fireplace hoods themselves can consist of two parts - an aggregate with a motor and filters and dome. Both parts are attached independently of each other, but so that their outlets coincide.

Separately, it is worth saying about island hoods. They are attached to the ceiling. In the kit there is a suspension system and clear recommendations on what and how to do.

Stages of mounting

The entire process of installation and connection can be divided into several stages:

- First you need to set the exhaust to the right place. It involves the physical mounting to the wall or ceiling.

- Second Stage - Connecting to Power Supply. If there is not far the socket, there should be no difficulties. Otherwise, it will have to pull the wire from the nearest source, as a temporary measure, you can use the carrying (extender).

- The last stage is relevant only for models with an exhaust air output into the ventilation system. At this stage, the air duct is connected and its output to Ventkanal.

Properly hang hood in the kitchen with your own hands easy

If there is a socket nearby, there is no problems with connecting to electricity. Other stages are also not very complicated, but consider them in more detail.

Fastening to the wall of the hinged or dome model

At least, outwardly, these two models are distinguished, they are attached to the wall. On the back wall of the case they have four holes - two left, two are on the right. Many manufacturers provide their products by the mounting pattern, which marks the location of the fastener. All that is necessary is to learn the template to the wall, transfer the mark. If there is no template, measure the distance between the holes, transfer to the wall. If there is an assistant, you can also be asked to hold on the selected altitude, and make markers yourself.

Fasten the hood to the wall it is necessary through the footing holes in the case

Next, everything is simple: with the help of a drill, we make holes of the appropriate size, insert plastic plugs of the dowels, then hang out the hood on the dowel-nails. Naturally, check the horizontal equipment of the installed equipment.

This method is good if the wall is smooth and does not interfere. Often next to the stove passes a gas pipe that does not make it possible to fit the hood close to the wall. In this case, you can nourish wooden bars on the wall, and to the bars it is already attached to the hood. This is a simple option, but not very good - the bars are covered with soak and wash them difficult.

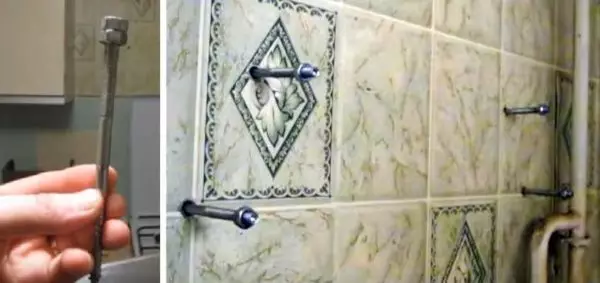

The second option to set the hood behind the pipes is to use a screw-stud (the second name of the stud plumbing). They have a thread for screwing into the wall, a smooth part, which makes it possible to attract a hood at a certain distance from the wall and a smaller thread with two nuts, which we will fix the body. There are these studs of different sizes, choose which you need, but all the nuts are made under the bit or an octailed key.

How to set a hood on the wall, if the gas pipe or the wall is hijacked

This embodiment is universal, simple, reliable. It is also more convenient for care - the metal is usually stainless, it is easy to wash it from deposits.

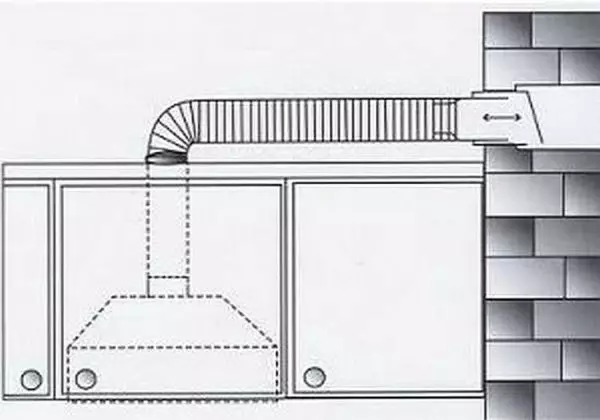

Installation of built-in hood in a closet

The embedded extractor is almost completely hiding in the cabinet made for her. It is attached exactly as described above - on screws, only they screw in the walls. Only pre-in the above shelves it is necessary to make holes for the air duct. This is done after the extraction of purchased, since the location of the air outlet depends on the company and model.

An example of installing built-in exhaust

If the locker is hanging, it is better to remove it. In the removed closet, set the exhaust to the place, mark the location of the air outlet on the bottom shelf, cut it out. To do this, it is easier to use an electrolovka and a pet with small teeth. Almost does not leave the chipset for laminate. If you wish to close the location of the cut, you can plastic C-shaped furniture profile. They are tough and flexible. Flexible use simply - it bends at any angle, hard before installation will have to warm up the construction hairdryer. These profiles "sit" on glue, most often used "liquid nails". After installation in place, remnants of glue (wet clean cloth) are removed, fixed with a painted tape to the shelf. Surplus profile Cut the saw with a small tooth, cleaned with small grain sandpaper.

The process of preparing a locker to install an exhaust

In the same way, we do holes in other shelves. By the way, they can already be non-round, but rectangular - depends on the section of the duct chosen by you.

After that, all the shelves are installed in place, the cabinet is hosted and fixed. The built-in extractor fastener is attached to it through holes in the housing. Next - the process of connecting the air duct.

How to connect an exhaust to electricity

Since the power consumption of kitchen hoods rarely, when exceeds 1 kW, they can be connected to conventional sockets. It is desirable that they were with grounding. This requirement must be performed if you want warranty obligations to be valid.

If the wiring in the apartment is old, you can throw the ground wire or rinse yourself. Just do not fix it to the pipes of the water supply or heating. It threatens the possibility of electrician or even a fatal outcome for you, members of your hones or neighbors.

To reach the ground wire, find the bus with the wires attached to it or the pipe to which the welded wire is fed. These devices can also be connected to your own stranded wire (without folding those that already exist). So that it normally worked the section should be 2.5 mm, the conductor is a multi-moist copper, the non-combustible shell is desirable.

Connect the hood through the Vago terminals

Part of the hoods goes with a fork at the end. With the connection of such models, no questions are in the outlet and that's it. But there are models in which the cord ends with wires. It is not from the greed of the manufacturer, and in order for the consumer himself to decide how it is better to connect equipment. If you want - you can connect the plug. This option does not fit - take the terminal block and connect through it. Another option is Wago Terminals. They must be taken three pieces - by the number of wires. In one terminal, connect the same wires from the hood and from the shield - phase with a phase (there can be different colors), zero (blue or blue) with zero, grounding (yellow-green) with grounding.

Duct for kitchen hood

One of the stages of the extraction setting is the choice and installation of air ducts. Air room temperature is given out of the kitchen, therefore there are no special requirements for air ducts and you can use any. Typically use three types:

- Aluminum corrugated sleeve. It is good in the fact that it is easy for him to give the desired shape - it is easily bent at any angle. Just take a piece of the desired length and give it the desired shape. Disadvantage: The work of the hood will be noisy, since the air flow causes noises and resonance. The second negative point is the surface ribbed, which creates additional difficulties for air flow. Well, one more disadvantage - it's hard to care: smoking with dust slaughters, sullen hard.

- Plastic (PVC) Round duct. Comfortable round polymer pipes. The air duct of the desired configuration is assembled from the shaped elements - roundings, taps, adapters, couplings. With the pipe, they are connected by the availability of extensions on the shaped elements. So that the elements are not disconnected during operation, the joints can be mounted with glue (liquid nails or torque). Another option is to be made by self-drawing - three or four pieces for each connection. The advantage of PVC air ducts for exhaust - they are "quiet", smooth inner walls do not create obstacles to air movement, external easily washed. The disadvantage is a more complex assembly process (compared to aluminum corrugation).

Types of ducts for kitchen hoods

- Plastic square air duct. Also produced from polyvinyl chloride (PVC), but has a rectangular cross section. All other characteristics are the same. Rectangular air ducts are used if it is necessary to save space - they are well hiding behind plasterboard partitions, behind tension or suspended ceilings.

There is another difference between the plastic and corrugated air duct - the price. Polymeric cost more. Despite this, if you have the opportunity to establish a hood using PVC, put them. With an equal cross section, they provide more efficient air removal, as well as fewer.

The pipe cross section for the air duct is determined by the size of the outlet on the exhaust. In the case of rectangular pipes use an adapter.

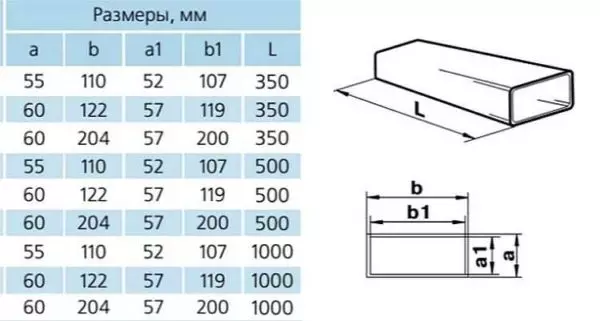

Dimensions of air ducts for exhaust

Round ducts have three sizes: 100 mm, 125 mm and 150 mm. This is the diameter of plastic pipes and corrugated sleeves. Sections of flat air ducts are greater and they are presented in the table.

Sizes of flat PVC air ducts for exhaust

How to choose a size? In the case of round pipes, their diameter must coincide with the diameter of the outlet of the exhaust. It is very undesirable to put an adapter on the output, and then use the air duct smaller diameter - this will reduce the air purification rate. And even if the exhaust is very powerful, it will not cope with the air cleansing.

With the choice of section of a rectangular duct - its cross-sectional area should not be less than the area of the section of the outlet nozzle. And the connection occurs through a suitable adapter.

How to fix corrugation to extract and ventilation

If you decide to set the hood and use for the air duct aluminum corrugation, you will need to think about how to mount it to the body and to ventilation. This will require clamps of a suitable size. They can be metal or plastic.

To connect an exhaust to the ventilation system, a special ventilation grille will also need. It has a hole in the top of the air duct pipe. At the bottom there are holes for removing air from the kitchen with the help of natural circulation at a time when the extractor does not work.

Mounting corrugations to the lattice on the wall

For mounting corrugations, a lattice is suitable with a protrusion - there is a side of the hole in a few centimeters, which is put on corrugation, after which it is attached using a suitable clamp.

In the same principle, the corrugated air duct is fastened. It has a protrusion, which is put on corrugation. Connection is tightened with a clamp.

How to fix the air duct to the walls

For plastic ducts there are special fastenings in the form of a latch. They first mounted on the wall using dowels. The installation step depends on the curvature of the route, but on average there is enough 1 fastening by 50-60 cm. In these latches, the pipes are inserted during installation with a small force.

If the air duct needs to be fixed on the ceiling, you can use the same mounts. But if it is necessary to withstand some kind of determined distance from the ceiling, this type of installation is not suitable. In such cases, they take perforated suspensions for drywall, attach them to the ceiling, then to them small screws PVC air duct for exhaust.

Methods for attaching corrugations

Corrugated air ducts to the walls are fastened with the help of clamps or plastic lighters of large size. To the ceiling, if necessary, they are also mounted using perforated aluminum suspensions.

Where and how to remove the air duct

Most often, the duct from the hood in the kitchen is connected to the ventilation hole through which natural ventilation is underway (by traction). It is incorrect, since the most of the lattice turns out to be a closed air duct, and through the remaining air exchange openings will be clearly insufficient.

A significant part of the ventilation grill is closed and ventilation in the apartment will be insufficient

Correct the air duct into separate vent rip. In this case, the same lattice is installed on the hole as in the photo above.

If there is no separate ventka channel, but the outer wall is located next to, you can remove the pipe to the street, putting the grille outside. These are two ways to have normal ventilation and ensure normal exhaust performance.

How to bring to the street

To set the exhaust and remove the air duct into the wall, you need to do the hole in it. And this is the only difficulty. Next, the air duct is inserted into this hole, climbing with a solution. Outside, the hole is closed with a grid - so that the garbage does not fall, birds and small animals sat down.

One example of an exhaust installation is not a kitchen with air output through the wall

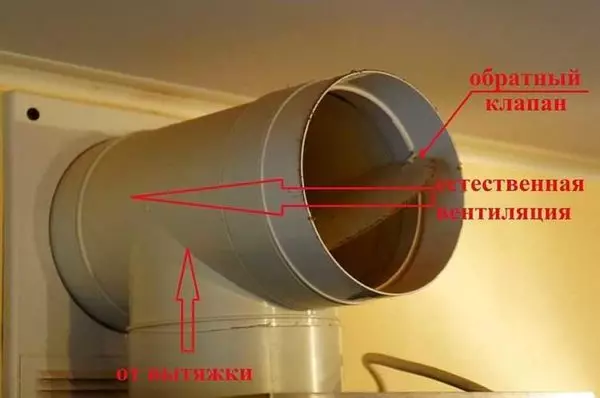

So that the air does not blow the room from the street, the check valve is installed (in the figure above it is designated by the oblique line). It is desirable to put it, by the way, when connecting the duct to the ventilation system - so that the smells of the pipes do not enter the room.

This looks like a reverse or anti-reflective valve for air ducts.

Reverse or anti-rader air valve is a light plastic or metal plate. It is movably fastened in two places to the pipe - at the top and bottom, the petals are supported by the rope spring. While the hood does not work, the valve overlaps the access of the air outside. When the hood turns on, the air flow flexs the plate forward, pressing the spring. As soon as the hood is turned off, the plate with springs returns to the place. If you set the hood without this valve, in the winter in the kitchen may be too cold - the outer air will be easily entering the room.

So that the extract does not interfere with natural ventilation in the kitchen

With the help of the tee and the check valve, it is possible, by the way, set the exhaust so that it does not interfere with natural ventilation in the kitchen. It will take a special ventilation grille for connecting hoods, check valve and a tee. A tee is fastened to the venerable to its lower input, an airbrew from the drawing is connected to its lower input, and the return valve is installed on the free output, then only so that the petals are locked when air from the pipe (in the photo below).

Anti-reflective valve for normal natural ventilation in the kitchen

How does such a system work? When the hood is turned off, the petals of the check valve are bent, the air from the kitchen in Ventcanal falls through the grille and the open output of the tee. When the extractor turns on, the air flow from it unfolds the valve plate, and the air goes to the ventilation system. When the exhaust is disconnected, the springs reappear the air access across the tee.

Externally, such a system looks not very attractive and it will have to mask it somehow. But this is the only way to connect the exhaust to the only existing ventilation output and do not reduce the air exchange.

Article on the topic: How easy and easy to make a bandage for curtains with your own hands