For repair work or during construction, a tool is required, which will quickly and efficiently work with wood, providing its smooth cut. Such a tool is a disk saw on a tree, work with it quickly and conveniently. But it is impossible to think that all the saws are the same, it is enough to buy the model and 2 replaceable cheap disks, and then start work. In fact, everything is much more complicated, when choosing a saw, you should pay attention to its capacity, specifications, working conditions with equipment.

Speed application scheme.

Special attention is required to be given to the saw disks, because it depends on them, which material can be processed, what kind of quality will be cut . All canvases differ in manufacturing material, shape and size, the turn of the teeth, other important parameters on which the quality of the cutting depends. Today manufacturers offer a large selection of wood processing equipment. When buying, it is necessary to pay attention to why discs are for what materials and types of wood.

Proper disk selection - Criteria for high-quality disk saw

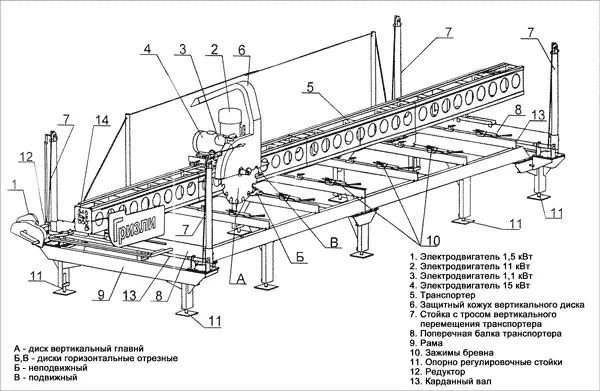

Homemade belt sawmill.

Choosing a power tool to work with a tree, it is necessary to pay attention to the selection of the cutting canvas. It is from it that depends largely, with which material it will be possible to work. Before choosing a diameter of the disk, it is necessary to take into account the rotational frequency, maximum and minimal speed.

To correctly select the saw blade, you must pay attention to such parameters:

- The type of work that is planned to be carried out. Consides what kind of wood work will be carried out.

- A series of saw blade where the sizes of the teeth are taken into account, their form, whether there are special plates.

- The design of the saw blade itself (shape of the tooth, bias, the presence of plates, their form, location, disk thickness).

- The outer diameter is selected with the frequency of rotation.

- The diameter of the planting opening takes into account the type of tool.

- Test parameters (thickness, shape, quantity, etc.).

Characteristics of wood disks

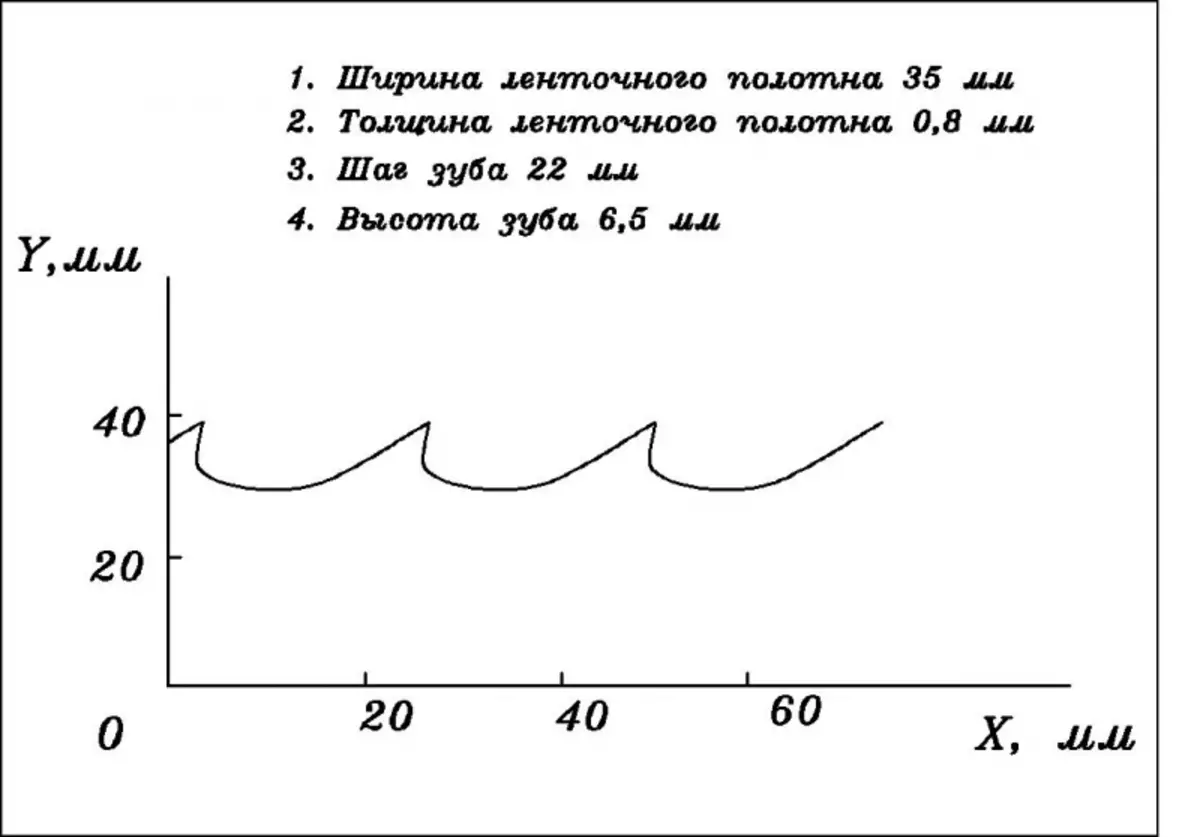

The profile of the belt of the belt saw.

When the disk saw and the canvas can be selected, you should immediately decide which the material will be processed, for what work the tool is needed. Today manufacturers offer a wide range, but all models are designed for specific works, so the choice must be given maximum attention.

Article on the topic: Corner photo wallpaper for two walls

For example, the speed of rotation may depend highly on what raw material requires processing. The selection of the diameter of the canvas depends on the frequency. We must consider the following data:

The dependence of the diameter of the disk from the speed of rotation of the equipment:

- diameter up to 80 mm - speed of rotation 23 800 revolutions per minute;

- diameter up to 100 mm at a frequency of 19,100 revolutions per minute;

- diameter up to 120 mm at a frequency of 15,900 revolutions;

- diameter 250 mm at a frequency of 7,600 revolutions;

- Diameter 300 mm at a frequency of 6,300 revolutions.

The larger the diameter of the saw blade, the speeds of rotation for the saw will be less. This is necessary to take into account during the choice of equipment and components to it.

The dependence of the velocity cut from the selected material:

- For soft wood, it is best to use speed within 50-90 m / s;

- for solid wood - 50-80 m / s;

- For laminate panels with any coating - 40-60 m / s;

- For exotic wood, the velocity is 50-85 m / s;

- For MDF panels, the speed of operation must be 30-60 m / s;

- For conventional carpentry, a speed of 60-80 m / s is required;

- For cutting plates, DSP also uses a speed of 60-80 m / s.

The shape of the teeth in the saw without Nakak.

When choosing a tool, it is necessary to take into account the fact that the peel teeth have a different shape, dimensions can be used at different speeds of work. As an example, you can consider such characteristics:

- At the parameter specified by the manufacturer in n = 1500 revolutions per minute, U = 10 m / min, Z = 60, Sz = 0, 11 mm saw discs can be used to cut the chipboard plate, solid and soft wood. Work can be accepted either along the fibers.

- At the parameter specified by the manufacturer in N = 3000 revolutions per minute, U = 5 m / min, z = 40, sz = 0.04 mm saw blades can be used for chipboard plates that have a polymer outer coating. They are suitable for cutting aluminum, laminated plates, plywood of different types.

It must be remembered that all manufacturers on the saw blades necessarily indicate the required parameters. You can easily determine which equipment is needed to perform planned work. But besides revolutions, thickness, speed and other indicators, it is necessary to remember that the disk saws are of different types, not only manual. It is necessary to determine the skate, for which tool is a specific saw blade.

Why is it important to choose the discs?

Technical specifications.

When question, how to choose saw blades for wood, it is necessary to pay attention to such parameters as the shape, the sizes of sawing teeth. Today manufacturers offer such models of discs for saws intended for wood processing:

- Carbide have special attacks that provide cross-saw. Products can be used for massive wood, it is used with a string of wood fibers, for chipboard plates with one and several layers, for solid and soft wood with solid cut requirements. The disk tooth has a trapezoidal form, it is made of solid alloys. Carbide saw discs that have cutting knives in the thicker, they are used for machine tools with automatic feed, providing high speed. Tooth has a straight form. Improved chip discharge occurs due to the proplining knives, a small amount of teeth. All this reduces the heating of the disk saw, resistance during cutting.

- Special saw blade with variable tooth, cutting special knives, reduced thickness for propyl. Such a disk is used only for longitudinal propyl, it allows you to make a thin and neat incision, the amount of waste is small. You can not use such canvas to work with the poplar. Tooth shape variable, it has a tilt by 10 °. The disk is used for two-, monitant multiple machines. The scope is soft and solid wood whose humidity is up to 15%. Silent discs for working with soft and solid wood have plates for sawing, located in the body. Used only for edged and multiple devices. The disk tooth has a straight form, during operation, high quality cutting is provided.

- Discs with variable teeth that can be used for pendulum, radial cutting. Such a model is used for a manual tool, with its helping can be provided with a transverse high-quality solid or massive, dried or wet wood. The shape of the tooth has a negative outer angle with a slope of 15 °. It is a similar disc for a saw that is considered one of the most optimal to perform work on the countryside, during the construction of the house, gazebos.

Article on the topic: Hovering curtains on hooks: The main stages of work

What disk saw is suitable for working with exotic and complex rocks?

Disk shapes for circular saws.

For manual disk saw, it is recommended to use a saw blade with a beveling tooth, which is great for a variety of construction work. Such a tool can be treated with a tree in a transverse or longitudinal direction, soft and solid wood, and cutting panels, bars that have nails, metal brackets and other low thickness fasteners are possible. Such wood saw saws are considered the best, since the scope of application is wide, and preparatory work (for example, the removal of nails) may not be required. The cost of the saw disks is not very high, it is usually about 2 times lower than for specialized.

For manual saws, drives with variable teeth are used, with which the composite panels can be processed, wood plates, phanel, massive soft, solid wood. The cut is possible in the transverse and longitudinal direction, the tooth itself has a front positive angle by 15 °. Such a disk is perfectly used not only with a hand tool, but also with disk circular saws.

To ensure a thin cut, if the tree is used massive, difficult to use special discs with variable teeth. They have a positive right angle and the so-called feed limiter. Work is obtained easy and fast, you can process materials that have even drop-down knots, which often causes a lot of problems even when using expensive discs.

In some cases, in the preparation of finishing materials from abrasive, exotic wood for the manufacture of panels, special disks are required that can cope with such a task qualitatively and quickly. For this, there are special canvas with a variable tooth having a slope of 15 °. Crop is provided in the transverse direction, you can apply them for format-cutting, conventional circular saws. It is possible to process such a material as soft, solid high-quality and expensive wood, laminated MDF panels with a thickness of 30 mm, chipboard with a thickness of up to 50 mm.

If you plan to work a manual saw saw with exotic rocks of wood, then you can use a disc with carbide attacks and a direct tooth.

In this case, it will be possible to paint the material along the fibers, while the disk saw perfectly cope not only with exotic rocks, but also very solid dry or wet wood, soft and wet.

Article on the topic: Bathroom washbasin stands

When choosing a saw for work, special attention must be paid not to the parameters of the equipment itself, but on the characteristics of the saw disks. It is from it that it depends on what kind of wood the saw will be able to cope, what conditions of work are possible. For example, there are discs that cope with almost any type of raw materials, but they cannot be called universal, as they do not fit for exotic breeds.