Ukunquma ubulungiswa bokulungela kwemishini yokushisa ukuze usebenze, kuyadingeka ukwenza umsebenzi wokuhlola okhethekile. Ngale njongo, ingcindezi inyuke ngokwezifiso emapayiphu, ngemuva kwalokho ukuqina kwengxenye ngayinye kwenziwa ngenxa yokungabikho okuphelele kokuvuza.

Kunezinhlobo eziningi zezinhlelo zokushisa: izivivinyo ze-hydraulic, ukuhlolwa kwe-pneumatic, ingcindezi yokuhlola.

Cabanga ukuthi ukuhlolwa kwezinhlelo zokushisa kwenziwa kanjani, yiziphi izigaba ngasikhathi sinye ezihambisana nazo.

Izivivinyo ze-hydraulic

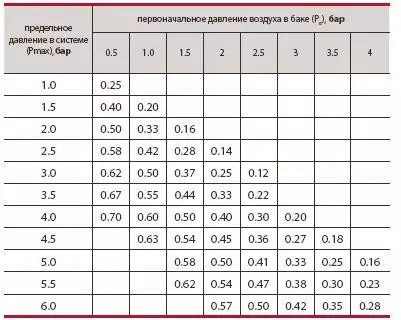

Ithebula lengcindezi yamathangi okwandiswa ukufudumala.

Ukuhlolwa kwe-Hydraulic kwamapayipi okushisa kuyinqubo ebhekele imishini yokuqeqesha esikhathini sokushisa. Ngasikhathi sinye, amapayipi agcwele amanzi kusuka phansi kuya phezulu, okungukuthi, ngokusebenzisa le pipeline ebizwa ngokuthi ukubuya. I-Liquid Medium nomoya ihamba endaweni eyodwa, wonke umoya ovela ohlelweni lokushisa ususwe ngokuphelele. Ukuhlola kuqala kuphela lapho wonke umoya uyakwazi ukuthola imininingwane egameni lengcindezi. Uma ungalindi, lapho izicubu zomoya zishiya amapayipi, izivivinyo zizophumelela amanga.

Ukuhlola ukufudumeza ngakho-ke kulandela izinhlelo ezivulekile, ngoba uma kukhona ukuvuza endaweni evaliwe (odongeni), uhlelo luthola izindawo zediphozithi kuzoba nzima impela, futhi kuvame nje. Ukwenza umsebenzi wokuqinisekisa, kufanele ulungiselele imishini enjalo:

- Iphampu ekhethekile yencwajana yomjovo ohlelweni lokushisa lomfudlana woketshezi;

- ukusebenza kwe-boiler efudumele;

- I-Manometer, ekhombisa ukuthi ngabe kukhona ukwanda noma ukwehla kwengcindezi ohlelweni olujwayelekile. Imininingwane enjalo izokhombisa ukunwetshwa kwamapayipi, ukuba khona kokuvuza.

Ukuhlolwa kwe-pneumatic

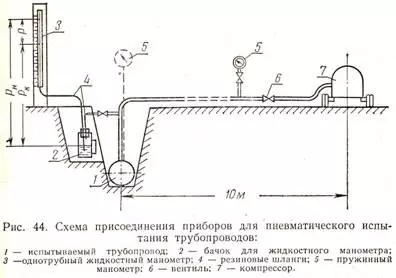

Uhlelo lokuhlola lwe-pneumatic.

Indlela ye-pneumatic ihlolwe uma izinga lokushisa elikhona liwela ngaphansi kuka-5 ° C. Kulokhu, ingcindezi kumapayipi akufanele incishiswe ngaphansi kwe-10 KPA. Le ndlela ilungele uhlelo lwamapayipi e-polymer, lapho izingxenye zokuxhuma zepulasitiki zenzeka khona.

Isihloko ngesihloko: I-Bed Clamshell yenze ngokwakho: Idizayini Yomkhiqizo

Imibandela yokubamba isivivinyo se-pneumatic sohlelo lokushisa yile:

- Uma kungekho uketshezi ngevolumu edingekayo;

- ekushiseni okukhona ngezansi kanye nama-degree amahlanu (abanye ochwepheshe bakhombisa - ngaphansi kwe-zero);

- Uma ngenxa yezizathu zobuchwepheshe awukwazi ukusebenzisa uketshezi olusebenzayo.

Akuvamile ukusetshenziswa. Lokhu kungenxa yokuthi ukuthola ukuvuza nokuvuza nokuvuza kunzima kakhulu kunokuhlolwa kwe-hydraulic.

Ukuhlolwa kwengcindezi

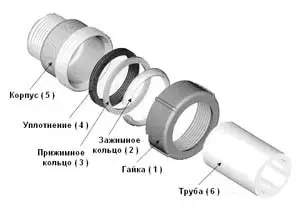

Isikimu sokuhlola ingcindezi.

Kuyini ukuhlolwa kohlelo lokushisa lokucindezela? Lokhu kungukuhlola ukuqina, okungukuthi, ukungabikho kokuvuza ngesikhathi sokusebenza kokuvimbela ukushisa kwesikhathi sokushisa. Ngezinhlelo ezahlukene, inqubo enjalo ingahluka kuma-trifles, kepha uhlelo olujwayelekile lokuhlola luhlala lufana.

Ukuhlolwa kwenziwa lapho kufakwa ingcindezi yokuqala, inkomba yayo ecishe ibe izikhathi eziyi-1.5 eziphakeme kunezinga lokusebenza. Isibonelo, uma ukusebenza kuyi-1 ATM., Okungukuthi, 0.1 MPA, izinga lokuhlola kufanele libe ngu-1.5 ATM. Kwamanye amanani, ingcindezi ngesikhathi sokuhlola ichazwa kahle futhi, okungukuthi, umsebenzi kumele wandiswe ngezikhathi eziyi-1.5.

Ochwepheshe bacebisa ukuthi uhlelo olujwayelekile olunezixhumo kumapayipi lungamelana kakhulu nengcindezelo, kumadivayisi amaningi okushisa kungathuthukiswa ngisho naku-2,5 MPA ngaphandle komonakalo wemishini.

Umsebenzi onjalo kungenzeka kuphela uma zonke izinto zohlelo lokushisa zingafakwanga edongeni, ukuphakama kwengcindezi eqinile kusebenza kuphela ohlelweni olujwayelekile lwendlu.

Ukucindezela kwengcindezi kumapayipi kusetshenziswa iphampu ekhethekile kuvame ukunwetshwa. Umoya ususwe ngokuphelele emapayipi, ngoba ngisho nobukhona bayo obuncane bungasebenza isibonakaliso sokucindezelwa kwepayipi. Phinda, ukufakwa kokushisa kumele kugcwaliswe ngokuphelele ngamanzi, amaphakethe omoya awavunyelwe.

Isihloko ngesihloko: ama-arches angaphakathi avela ku-plaster efulethini

Ukuze uthole ukufakwa kwe-Collector, faka ama-valves e-air duct. Kuleso sigaba samapayipi lapho ingcindezi inamanani aphezulu kakhulu, kuyadingeka ukufaka igeji ekhethekile yokucindezela. Lokhu kuvame ukuba yiphuzu eliphansi kakhulu kulo lonke ukufakwa kokushisa. Okulandelayo, inqubo ihlukaniswe izigaba ezi-2, zibabheke ngemininingwane eminingi.

Yini okufanele ukuhlolwa kokushisa: izinyathelo zokuhlola

Ukuhlolwa kwezinhlelo zokufudumeza kuqukethe izigaba ezi-2 ezivumela ubukhulu bokuhlola isimo semishini, ukulungela kwayo ukusebenza. Isigaba sokuqala sokuqinisekisa ukwenza inqubo ebizwa ngokuthi yinqubo ebandayo. Ukufakwa kokushisa kugcwele amanzi, ngemuva kwalokho imizuzu engama-30 (ngezikhathi ezithile zemizuzu engu-10-15), kuyadingeka ukukhulisa ingcindezi kumanani wokuqala wesikhundla.

Ngemuva kwemizuzu engama-30, ingcindezi akufanele iwe ngaphansi kuka-0.06 MPA. Ngemuva kwemizuzu engu-120 yokuhlolwa, akufanele kunciphe ngaphezu kwe-0.02 MPA. Ngemuva kokuthi isheke seliphelile, kufanele uhlole ngokucophelela isimo sakho konke ukuxhumana ukuze uqinisekise ngokugcwele ukungabikho kokuvuza okungenzeka.

Isigaba sesibili sokuhlolwa kwengcindezi senziwa vele kulokho okubizwa ngokuthi kuyashisa. Esimweni sokuqala, amanzi ayebanda, manje okushisayo, izinga lokushisa kufanele lisondele kwisisebenzi. Isivivinyo siqala ngeqiniso lokuthi i-boiler ixhuma ukufudumeza, okungukuthi, umthombo wokushisa. Kungaba yimiphi imishini esetshenziswa njengomthombo opholile. Ngemuva kwalokho, ohlelweni, wonke amapharamitha asethwe emazingeni aphezulu okusebenza, kepha kuyadingeka ukubhekisisa ukuthi ingcindezi ayidluli amanani avumelekile.

Ngaphambi kokuqala umsebenzi ngokuqinisekiswa, indlu kufanele yenziwe izinsuku ezintathu - lesi ngesinye sezimo zokuhlola okuphoqelekile. Uma ngesikhathi sokugcwaliswa kokuvuza kwamanzi okushisayo akubonwa, khona-ke singacabanga ukuthi ukuhlolwa kohlelo lokushisa sekudlule okuhle kakhulu.

Isihloko ngesihloko: Ungathunga kanjani uthayi ngamakhethini

Ukuhlola imininingwane yepulasitiki

Lapho uhlola, kuyadingeka ukubheka ukuthi ngabe kunezingxenye zepulasitiki. Lokhu kuchazwa yiqiniso lokuthi ukwanda okushisayo kwepulasitiki kunezinkomba eziphakeme, kusho ukuthi izinga lokushisa lamanzi ohlelweni kanye nokushisa okukhona kufanele kube njalo. Ngoshintsho ezinkombeni zokushisa nokungalandelwa ngokuqina, ingcindezi ohlelweni lokushisa isakwanda.

Lapho uvivinya imishini, ingcindezi kufanele iphakanyiswe kunani elidlula amahlandla acishe abe yi-1.5, ngemuva kwalokho likubambe imizuzu engama-30. Uma kukhona isandiso emapayipi, kuyadingeka ukuwala kancane izinga lokucindezela, ngemuva kwalokho okudingekayo ukuze uqhubeke nokuhlola, ubheka amanani aqhubekayo. Ngemuva kwemizuzu engama-30, kungenzeka ukuthi wehlise kakhulu inani elisezingeni elisengxenyeni yesisebenzi, ukusibamba ngale ndlela imizuzu engama-90.

Uma ukwanda okuncane kubhekwa, akusho ukuthi yikuphi ukwanda kumapayipi, kepha mayelana nokuqina kwalo lonke uhlelo. Kunconywa ochwepheshe abaningi lapho beqhuba amasheke banciphise futhi bandise izinga lengcindezi ukuze lisho ngokunembile ngokusebenza kwalo lonke uhlelo lokushisa, amandla okuthatha noma imiphi imithwalo (lilinganiselwe ngamanani achazwe ngumenzi).

Ukuhlola ukufakwa kwe-Heating kwenziwa ngezindlela ezahlukahlukene, kufaka phakathi ukukhuphuka / ukwehla kwengcindezi kumapayipi. Lapho wenza imisebenzi enjalo, kuyadingeka ukulandela imiyalo ngokunemba ukuze kungabikho amakhefu, ukuqina kokuqina. Ngasikhathi sinye, kufanele kubhekwe nezici ezithile ezinomthelela oqinile ekuhambeni kwenqubo yokuqinisekisa, ngokwesibonelo, impahla ekhiqiza izinto ezibonakalayo. Vele uqiniseke ukuthi yonke into ihlelekile, ungaqala ukuxhashazwa ngaphandle kokukhathazeka ngokuvuza okungazelelwe.