To determine the degree of readiness of the heating equipment to work, it is necessary to conduct special test work. For this purpose, the pressure is artificially increased in the pipes, after which the tightness of each compound is carried out for the complete absence of leakage.

There are several types of heating systems: hydraulic tests, a pneumatic test, pressure test.

Consider how the test of the heating systems is carried out, what stages at the same time are complied with.

Hydraulic tests

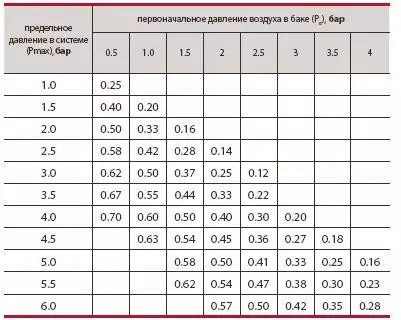

Table of pressure of expansion tanks heating.

Hydraulic test for heating pipes is a responsible process of training equipment to the heating season. At the same time, the pipes are filled with water from the bottom up, that is, through the so-called return pipeline. Liquid medium and air moves in one direction, all air from the heating system is completely removed. Testing is starting only when all the air goes to be able to get the data from the pressure gauge. If you do not wait, when the air masses leave the pipes, the tests will turn out false.

Checking heating thus follows open systems, since if there are leaks in a closed (in the wall), the system finds the deposit places will be quite difficult, and often it is simply impossible. To perform verification work, you should prepare such equipment:

- Special manual pump for injection into the heating system of the working fluid stream;

- working heating boiler;

- Manometer, which shows whether there is an increase or decrease in pressure in the general system. Such data will indicate the expansion of pipes, the presence of leaks.

Pneumatic test

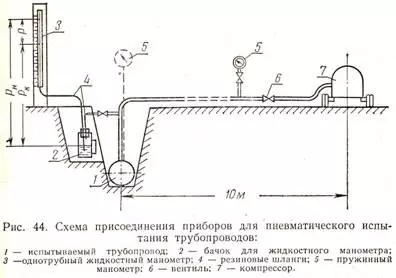

Pneumatic Test Scheme.

The pneumatic method is tested if the ambient temperature falls below 5 ° C. In this case, the pressure in the pipes should not be reduced below 10 kPa. This method is perfect for a system of polymer pipes, where plastic connecting parts takes place.

Article on the topic: bed clamshell do it yourself: product design

The conditions for holding a pneumatic test of the heating system are:

- in the absence of fluid in the required volume;

- at ambient temperature below plus five degrees (some experts indicate - below zero);

- If for technical reasons you can not use the working fluid.

It is rarely used. This is due to the fact that finding leaks and leakage and leakage are harder than in hydraulic tests.

Pressure test

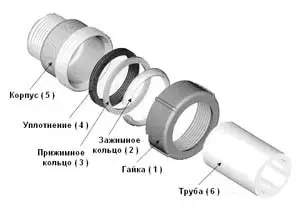

Pressure test scheme.

What is the test of pressure heating system? This is an inspection for tightness, that is, the absence of leaks during the functioning of the heat resistant to the heating season. For different systems, such a process may differ in trifles, but the general scheme for checking remains the same.

The test is carried out when the initial pressure is submitted, the indicator of which is approximately 1.5 times higher than the level of the working. For example, if the working is 1 atm., That is, 0.1 MPa, the level for checking should be 1.5 atm. For other values, pressure on the test time is defined exactly as well, that is, the working must be multiplied by 1.5 times.

Specialists advise that the general system with couplings in pipes can withstand the pressure even more, for many heating devices it can be enhanced even up to 2.5 MPa without damage for equipment.

Such work is possible only if all the elements of the heating system are not mounted into the wall surface, a strong pressure lift applies only for an open heating general system of the house.

Pressure pressure in the pipes using a special pump is usually manual. The air is completely removed from the pipes, since even its small presence can serve a signal of depressurization of the pipe. Repeat, the heating installation must be completely filled with water, air pockets are not allowed.

Article on the topic: Interior arches from plaster in the apartment

For collector installations, install air duct valves. On that section of pipes where pressure has the highest values, it is necessary to install a special pressure gauge. This is usually the lowest point for the entire heating installation. Next, the process is divided into 2 stages, consider them in more detail.

What should be the test of heating: steps of testing

The test of heating systems consists of 2 stages that allow the maximum to check the condition of the equipment, its readiness to work. The first stage of verification is to perform the so-called cold process. The heating installation is filled with water, after which for 30 minutes (at intervals of 10-15 minutes), it is necessary to increase the pressure to the initial position values.

After every 30 minutes, the pressure should not fall lower than 0.06 MPa. After 120 minutes of tests, it should not decline more than 0.02 MPa. After the check is over, you must carefully inspect the status of all connections to fully ensure the absence of possible leaks.

The second stage of pressure testing is carried out already in the so-called hot. In the first case, the water was cold, now the hot, the temperature should be close to the worker. The test begins with the fact that the boiler connects to heating, that is, the heat source. It can be any equipment that is used as a coolant source. After that, in the system, all parameters are set at the maximum working level, but it is necessary to closely monitor that the pressure does not exceed these valid values.

Before starting work on verification, the house should be performed for 3 days - this is one of the mandatory test conditions. If during the filling of hot water leaks is not observed, then we can assume that the test of the heating system has passed excellent.

Article on the topic: How to sew a tie for curtains

Plastic Detail Checking

When testing, it is necessary to consider whether there are plastic parts. This is explained by the fact that the thermal expansion of plastic has high indicators, it means that the water temperature in the system and the ambient temperature should be permanent. With changes in temperature indicators and non-compliance with tightness, the pressure in the heating system will still increase.

When testing equipment, pressure should be lifted to a value that exceeds the working approximately 1.5 times, after that it holds it for 30 minutes. If there is an extension in the pipes, it is necessary to slightly drop the pressure level, after which it is necessary to continue checking, observing constant values. After 30 minutes, it is possible to dramatically lower the value to the level constituting half from the worker, to hold it in this way for 90 minutes.

If a small increase is observed, it does not say any expansion in the pipes, but about the tightness of the entire system. Many specialists are recommended when conducting checks repeatedly reduce and increase the level of pressure so that it can accurately say about the performance of the entire heating system, the ability to take any loads (limited by the values specified by the manufacturer).

Checking the heating installation is carried out by various methods, including the increase / decrease in pressure in the pipes. When performing such works, it is necessary to follow the instructions in accuracy so that there are no breaks, tightness disorders. At the same time, certain factors should be taken into account that have a strong impact on the flow of the verification process, for example, the material manufacturing material. Just make sure that everything is in perfect order, you can start exploitation without worrying about sudden leaks.