The machine for production of plasterboard profiles is the central object of the entire system for the manufacture of framework parts for drywall structures. Modern equipment makes it possible to do a variety of profiles, and therefore the manufacture of details of the calcareblock for drywall are considered by many as a very promising direction in business development.

In our article, we will talk about the peculiarities of the production process, as well as which elements include a line for the manufacture of metal products.

Equipment for the manufacture of metal

Profile for plasterboard

Nomenclature of metal products

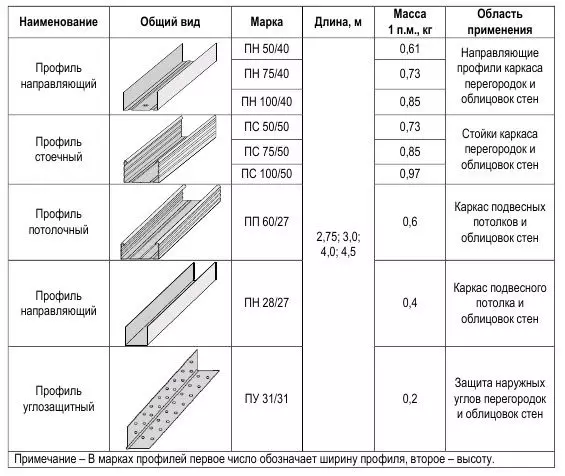

The basis of most drywall structures is a metal frame collected from special profile elements. The size of these parts and their configuration determines the mechanical properties of the frame for drywall, and therefore, they are largely affected by the characteristics of the structure as a whole.

To date, the most common types of profiles for GCC are:

- Ceiling (CD) Plasterboard Profile - Used as a base for suspended ceilings, as well as wall structures of small dimensions.

- Wailed (UD) - attached around the perimeter of the room as a support for the ceiling.

- Stationy (CW) - Replaces to build vertical frame elements, is characterized by improved mechanical characteristics.

- Stressed (Door) (UA) - more durable than the other types of frame parts, is used mainly to assemble the frames of door openings in interior partitions from drywall.

One of the options for classifying frame elements

In addition to these elements, which refer to the category of basic, a significant number of additional components - suspensions, brackets, connectors, extension cores, etc. are represented on the market. All of them are used to assemble frameworks under the walls of the walls and ceilings with plasterboard.

For the production of all these elements, special machines for the profile for drywall are used. To date, the manufacture of long modules for mounting the designs from the hypinet is a fairly popular area of private business.

Note!

Consumption volumes, and therefore, the volume of manufacturing elements of the crate for structures from GCCs directly depend on the volume of consumption of the drywall itself.

Features of the production process

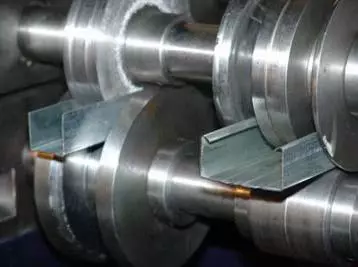

Different profiles for mounting drywall are produced from galvanized steel. In their production, cold bending technologies or metal stamping technologies are used.

Article on the topic: At what temperature you can pour a concrete tie

Raw materials for production - Steel tape

For the manufacture of these products, the following features are characterized:

- Raw materials - thin galvanized steel. Mark steel 08-KP, the choice of material is regulated by GOST 9045-80.

- The optimal thickness of the workpiece is 0.4-0.65 mm. Each machine for making a profile for drywall is designed to work with the billets of a certain thickness, which should not be exceeded due to the risk of early wear of the machine nodes and the failure of it.

- Billet width - from 120 to 180 mm. Some automatic lines are capable of working with larger blanks, however, the price of such equipment is high enough.

- The maximum length of the finished product is from 4 to 6 m. This parameter depends on the dimensions of the machine receiving table and, if necessary, can be increased without cardinal reconfiguration of the entire line.

The procedure for forming a profile from a metal blank is shown on video posted on our resource.

Equipment for rental

Basic elements of the profile production line

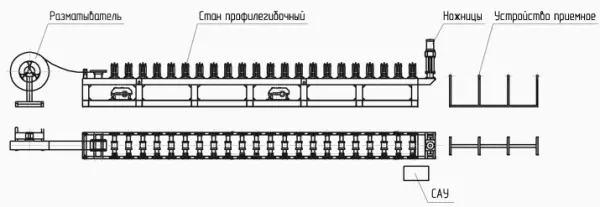

Despite the fact that devices for the manufacture of metal parts of the crates from different manufacturers differ in design, the overall scheme of the functioning of such systems remains unchanged.

As a rule, a profilegile machine includes:

- Spotchler is a device for feeding a tape preparation for processing. In most models of bending machines, console unwitters are used, the use of which provides automatic feeding material on bending.

Rolling station

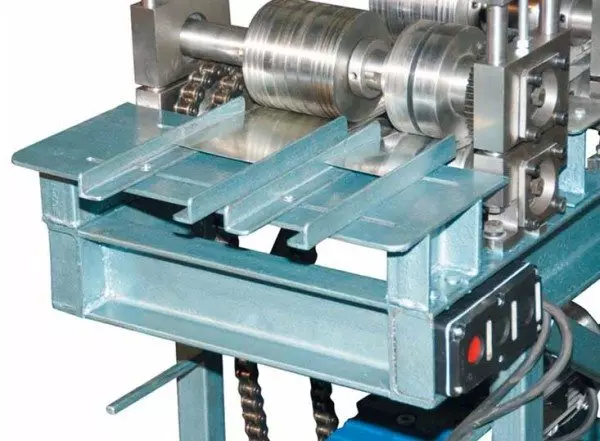

- Rolling mill. The main element of the line responsible for profiling of the workpiece. Depending on the type of line, the rolling mills can produce profiles as a single size and several times without reconfiguration. Naturally, for the production of a wide range of products, the second variety is more preferable.

- Cutting device, as a rule, pneumatic scissors. The main task of this node is trimming finished products according to a given dimensions. The best models of scissors are equipped with batting systems like "bat-cutting", which allows pruning a profile without stopping the rolling mill. The accuracy of the cutting is +/- 5 mm from the specified parameters.

- The receiving table is responsible for the warehousing of finished products.

Article on the topic: Installation of balcony kV antenna

Machine for production of plasterboard profiles: element location scheme

You can see the diagram of the profile manufacturing line in the photo.

In addition to the already mentioned elements of equipment for the manufacture of metal rolling, the mandatory component is the control system. As a rule, such a system comes with the equipment and runs under the certified software.

Note!

The use of automated control systems provides improved quality of finished products by eliminating the influence of the human factor.

Features of the choice and commissioning of production

By and large, the main number of lines presented in the market are characterized by quite worthy quality and performance.

And yet, planning to open a profile rental business for GLC, you need to take into account the following:

Rolled Production Line in Action

- It is better to acquire a domestic or European machine for the production of a profile for drywall - China, although it has more democratic prices, somewhat inferior in quality.

- An important factor when choosing must be the services for setting up the machine line. For example, many companies offer buyers of equipment comprehensive assistance in setting up all business processes, up to signing contracts with suppliers of maximally suitable raw materials.

- Also, do not forget the setting and calibration of the equipment. Of course, the instruction is supplied with any machine with any machine - but without the presence of the appropriate skills for the setting, you should not take your hands. This is exactly the case when attracting specialists from the side will be fully justified!

As you can see, choose the appropriate machine for the plasterboard profile - it is still half an end. But if you select the desired equipment, effectively configure it and competently organize the workflow, the production of parts for plasterboard trim may well become a source of solid income!