Tile ea li-crumbs tsa rabara ka har'a 'marakeng oa moaho o ile a hlaha haufinyane tjena. Sehlahisoa sena ke ho koalla ka mokhoa o bonolo o hlahisitsoeng ho tsoa botebong ba rabara o sithabetseng, e tlamisa motsoako oa daerethane le daes. Lisebelisoa tse ka sehloohong tse tala ke lithaere tsa likoloi tsa boleng bo holimo, tse entsoeng ka rabara tse phahameng tsa boleng bo holimo e nang le sebopeho sa bonyane li-rabara tse 50%.

Mabili a hloekisitsoeng ho tsoa ho thapo ea tšepe a le fatše ka sekhahla sa mochini kapa sethaleng sa karoloana ea karolelano ea 0,4-10 mm. Ka thuso ea lisebelisoa tse khethehileng, lisebelisoa tse hlahisitsoeng li tsoakane le likarolo tse ling kaofela, ka har'a mefuta ea polasetiki, 'me e kopantsoe le vibrate.

Mekhoa ea 2 ea ho hatelloa ho hatellang e sebelisoa:

- Ka mokhoa o batang, lijana tsa bolding li tletse sebopeho sa rabara se kenngoa ka cabinet ea ho omisa bakeng sa lihora tse 6-8.

- Ka ho tobetsa ho chesa, likokoana-hloko le ho hlakoloa ha lithaele li etsoa ka nako e le ngoe mochesong oa ho isa ka la 140 ° C bakeng sa metsotso e 140 °.

Ts'ebeliso ea Ts'ebeliso

Thaba ea rabara e ratoa ebile e batla, e sebelisitsoe libakeng tse fapaneng. Ho tobana le sefahleho sa rabara ho sebelisoa tokisetsong ea lintho tse latelang:

- Mefupano ea maoto, lipina le litsela tse ka lipere li le lirapeng, metsaneng ea naha le likatse tsa naha;

- libaka tsa ho bapala tsa lipapali ka ntle le ka tlung (e fokotsa kotsi ea likotsi tsa bana);

- Li-Purms, Gadiums, mabaka a lipapali le ho ikoetlisa;

- meaho ea kichine;

- Banngon (Lekala la Maanase (Lekala la Tsoho le Pele ho Banner);

- masimo a haufi le li-rinks, matamo, seliba, seliba sa maiketsetso, jj.;

- likoloi tse koahetsoeng le karache;

- Libaka tsa Lehae;

- likhohola, balconnies;

- li-craride le meropa;

- menyako ea meaho ea bolulo le litsi tsa ofisi;

- meaho ea literateng tse kang mathule, tsela kapa litepisi;

- Tlhahiso, ho ea mabenkeleng, matloana le lithupelo.

Litšobotsi tsa lipoleiti tsa rabara

Li-paramente tsa tekheniki tse nang le li-slaves tse tšolotsoeng li tjena:

- Botenya ba sehlahisoa - ho tloha ho 10 ho isa ho tse 55 mm;

- Bolulo ba thepa - 850-1000 kg / m³;

- Sebopeho ke seretse sa rabara ho 90%;

- ho loka ha metsi;

- Boima 1 lithaele - ho fihlela ho 7 kg;

- Bophahamo bo bolokehileng ho oeleng - 0,8-1.8 m;

- Tile e Akaretsang e Akaretsang le ho Qoba Mehala ea Mafula

- hanyetsa li-punters tsa lik'hemik'hale (peterole, oli le nakoana le alkalis le acids);

- Bophelo ba tšebeletso bonyane lilemo tse 15.

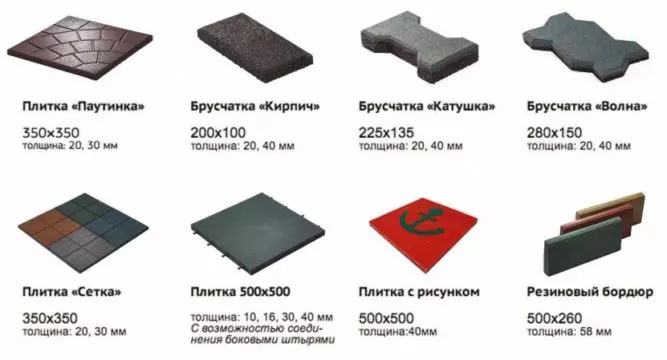

Tile ea rabara e entsoe ka mefuta e fapaneng le boholo bo 'maloa (0.35 * 0,35 * 0,5 * 0.5 m).

Melemo le mathata

Ho koaloa ha lithaba ka rabara, joalo ka lintho tse ling tse ling tse qetellang, li na le litšoaneleho tse 'maloa tse ntle le tse mpe.

Melemo ea lihlahisoa tsa rabara tsa rabara li kenyelletsa litšobotsi tse latelang:

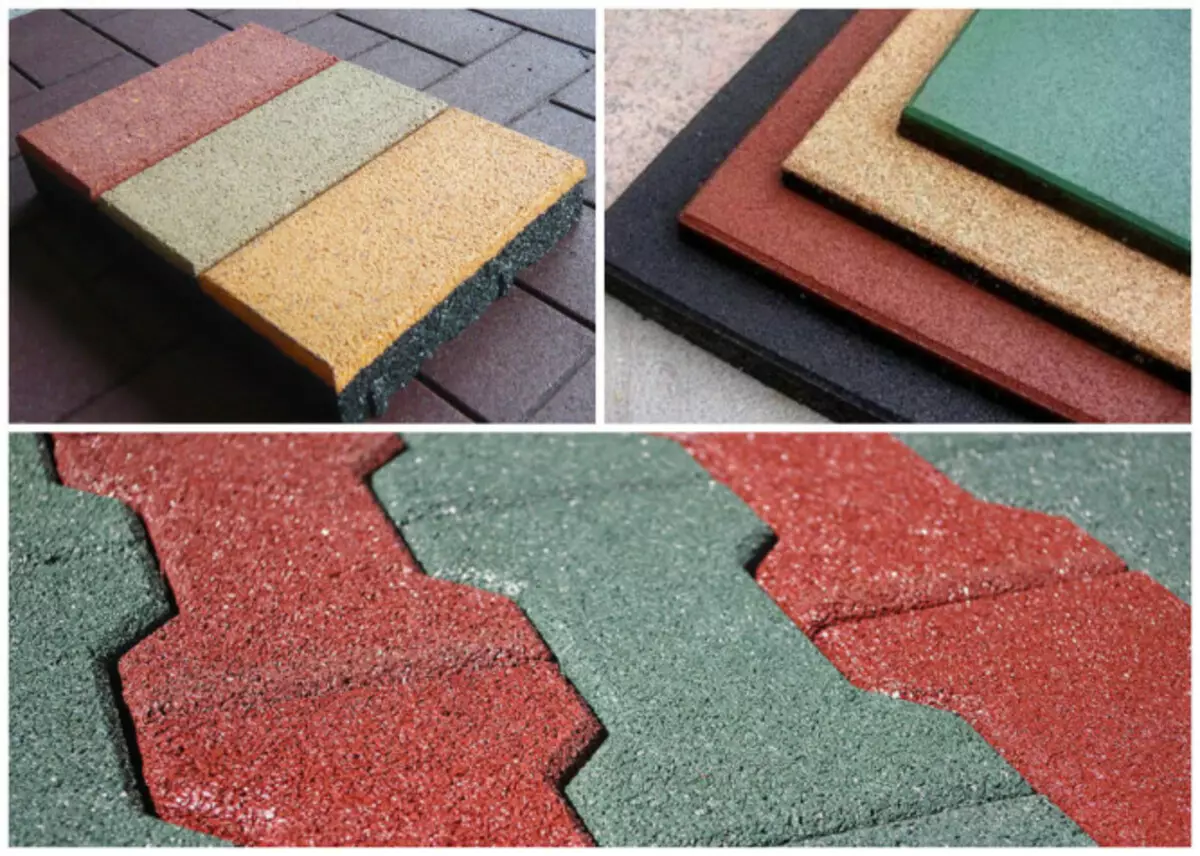

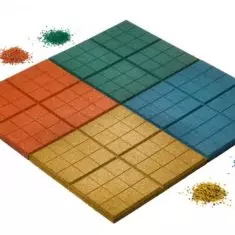

- Phallente e pharaletseng ea mebala (khabisa);

- Tile, e jarang metsi le ho seprofi sa metsi (bakeng sa seterata le bakeng sa ntlo);

- Matla a phahameng le ho khathala;

- botsoalle ba tikoloho;

- nolofalloa ke ho kenya le ho nyahamisa;

- nolofalletsa lipalangoang;

- Ho hanyetsa mahlaseli a ultraviolet;

- ho bonolo ha ts'ebetso le tlhokomelo;

- ho feto-fetoha le maemo le ho hlaka (ho sa tsotelehe mocheso);

- Tile ke likotsi tse bonolo le tse sireletsehileng (tse hatelletsoeng ha li oela ho eona);

- Eseng ho thella (e fana ka grip e ntle);

- Lerata le phahameng la lerata la ho senya matšoao.

Sengoloa ka sehlooho: Hlotsi e ntšo e hlahile ka kamoreng ea ho hlapela, ho e tlosa joang

Letšoele le tsoang Rubber le na le mathata a lokelang ho tseba. Litsebi li utloisisa liphoso tse latelang tsa lithaba tsa rabara:

- Taba e phahameng ha e bapisoa le li-slabs tse halikiloeng, tsa konkreite le tse ipatileng;

- Ho hlekefetsoa mollo - rabara ho ke ke ha sebelisoa, kahoo, thekollo e ke ke ea sebelisoa mollong o bulehileng (onplals

Malebela a ho khetha

Ho khetha ka nepo le ka nepo ho khetha tloaelo ea rabara, u lokela ho tseba hore na ke mabaka afe a tla beoa mabaka le hore a ka sebelisoa joang. Tile e entsoe ka boholo bo fapaneng ka kakaretso.

Ha u khetha botenya ba lintho tse tobileng, lintlha tse latelang li nahanela:

- Bakeng sa setsi se tiileng (sa lehlabathe, lehlabathe, lehong jj.) Ho molemo ho khetha thaona ka bophara ba 1-2.5 cm.

- Bakeng sa softer lehlabathe le likepe tsa mobu, likokoana-hloko li loketse botenya bo boholo (bonyane 3-4 cm).

Mefuta e akaretsang ea lintho tsa rabara e khethoa ho latela likhothaletso tse latelang:

- Lipinana, litsela, libaka tse bulehileng li tsamaisoa ke medulo e nang le boholo ba 0.5 * 0.5 m.

- Bakeng sa tokisetso ea meaho ea lipapali, libaka tsa lipapali tsa bana, li-terces, li-tempe tsa tereke, tse fanang ka tšebeliso ea likarolo tsa 0.35 m.

- Ka likamoreng tse nang le sebaka se seholo (borashe ba ho paka, ho hlatsoa likoloi, ho hlatsoa likoloi, jj.), Lihlahisoa tse kholo li sebelisoa - 1 * 1 m, 1 * 0,5 m.

Lethathamo la lisebelisoa

Ho beha rabara ea rabara ka matsoho a bona, lisebelisoa le lisebelisoa tse latelang li tla hlokahala:

- li-module tsa li-pered from rabera;

- Bokhoni ba motsoako o khanyetsanang;

- Rubber hammer (Cyrichane);

- Sesebelisoa se sehiloeng se sehiloeng (thipa, elektroniz, Hacksaw, jj);

- lisebelisoa tsa spatula bakeng sa ho sebelisa sekhomaretsi;

- boemo ba kaho;

- Tharollo ea sesepa;

- Rabara meeli e koalang likarolo;

- tjhoko kapa kaho ea penshene;

- mastic kapa glue ea rabara;

- Skilidar, Acetone;

- Roulette kapa mola o molelele;

- Litlolo, brashi, scoop kapa vacuum hloekisa;

- Sponge Rubber oa foam bakeng sa ho tlosa sekhomaretsi se feteletseng.

Ha Glue ea Rubber Tile

Morero oa theknoloji le mokhoa oa ho beha lingoliloeng tsa rabara tse halikiloeng ho latela tekanyo ea bongata metheo eo e tlametsoeng ho eona. Ha o bapala lese e tiileng, lintho li ka oela holimo li sebelisa sekhoba sa polyurethane. Sebetsa ka libaka tse sotla tse bonolo le tse ntle tsa tšebeliso ea likarolo tse khomarelang ha li fane.Mahlale a ipehang

Theknoloji ea ho boloka lithaelese ea rabara e khethoa ke thepa ea setsi (bulk kapa e tiileng) le litšobotsi tsa motho ka mong).

Litsebi li arolelana mekhoa e 2 ea ho kenya karolo ena ea bokahohleng: fatše le setsi se tiileng sa tšehetso.

Ka masoabi

Ka kopano ea mobu, tlhokomelo e khethehileng e lefuoa ka hloko. Pele u robala fatše, ho hlokahala ho theha motheo oa likarolo tse 3 tse ka bonang mojaro o sebetsang hantle.

The Motheo ka tlasa Tile ea rabara e na le e latelang:

- Ho ts'oaroa ha tšimo ho etsoa. Bakeng sa sena, mekoallo e hlokometse meeli ea sebaka seo, joale ho hlokahala hore u otlolle thapo kapa ropo.

- Sebaka se khethiloeng se lefelloa linthong tse sa hlokahaleng (likotoana tsa khalase, majoe, jj.)) Le limela.

- Sebopeho se nonneng le sesosa se ka tlase ho isa botebo ho isa ho 21-25 cmwe li tlosoa.

- Sebaka sa marang-rang se tahiloe ka botlalo ke vibropilet e nang le motsamao oa motlakase kapa traname ea buka, e ka etsoang ka matsoho.

- Lejoe le chabetsoeng haholo (2-4 cm) le tšolotsoe sebakeng se lokiselitsoeng le se shebileng hantle. Bothuta ba bokaho ba khoho bo khethoa ke sepheo sa ts'ebetso sa ntho. Bakeng sa mokhatlo oa litselana tsa jareteng le litselana, sebakeng sa papali ea lipapali tsa bana se tla hloka bonyane 10 cm, sebaka sa ho paka makoloi - ho tloha ho 20 cm.

- Sekhahla sa rubble se ajoa ka ho lekana le ho hatelloa.

- Mothating o latelang, sebata sa lehlabathe ke bonyane ba 5 cm. Ho hotle ho loanela ho tlatsa boitlamo bo setseng le bosholu.

- Peemateng oa sebaka, ho hlokahala ho kenya moeli o khethehileng oa rabara, o tla matlafatsa motheo ebe o fana ka sebaka se tiisitsoeng sebakeng se felisitsoeng.

- Karolo ea ho qetela ea li-stwork e nang le bophara ba lik'hilomithara tse ka bang 7 ho tloha motsoako o omileng oa samente (M400 Brand ka lehlabathe ho 1: 6. E kopantsoe ka hloko le kotsi.

Sengoloa ka sehlooho: Hobaneng ha crane e khumamela ha metsi a buloa ka seo a lokelang ho se etsa

Hona joale merusu e phetheselang e behiloe ka tsela e 'ngoe. Ho ba le letoto la letoto ho beoa leihlo le sebelisa boemo ba kaho ea bubble le leng le le leng. Ha ho na lebaka la ho etsa khethoa ea tlhaho bakeng sa drainage ea metsi a leholimo, kaha metsi a tla feta ka lintho tse halikiloeng le manonyeletsong. Lintho li loketse ho ba le liseke tse khethehileng kapa tse nonchang (haeba ho na le) ebe li tšela ka hamore ea rabara.

Lintho tse setseng lipakeng tsa marang-rang a mantlha le moeli li tletse ho kuta. Lithaka li hatelloa ka thata, likheo ha lia lokela ho lula li sala. Hoo e neng e felisitse rabara e tepelletse ka hloko 'me e fafalitsoe ka lehlabathe, e tla tlatsa likheo tsohle le ho hloka thabo. Kamora lihora tse ka bang 24, sethala se ka sebelisoa.

Basebetsi ba lirapa ba ile ba beha lipampiri tsa litheko ho tloha fatshe ka lebaka la ho hlophisa substrate. Ho etsa sena, sebaka seo se ne se phekotsoe ke limela, li lula li le mokopi, ebe se ile sa hlatsuoa hantle. Lithaele li beoa holim'a mobu ebe li tsepame hammoho le e mong ka likarolo tse khethehileng tse hokahanyang. Qetellong ea nako ea lehlabula, koae e joalo e tsielehile ebile e tlositsoe bakeng sa polokelo.

Ka konkreite

Ho roka lithaelese ka setsing sa konkreite ho etsoa theknoloji e tšoanang, ke mohato feela oa boitokisetso ba lefatše o fapaneng. K'honki ea konkreite ha ea lokela ho ba le likokoanyana (lichifi, mapetso, jj.), Joalo-joalo le eona le ho ferekanya. Litsi tsohle li hloka ho khalemeloa, haeba ho hlokahala, ho lokisa Sehoa se Sehiloeng, se hlabiselitsoeng ke mapetsi le lipeka.

Ebe bokaholimo bo hlakoloa litšila le lerōle. Ho ntlafatsa hod'enon, sefofane se sebetsang se thehiloe ka sebopeho se lokiselitsoeng ho tloha sekhobo sa Polyurethane setulong le turbidar kapa acetone (1: 1). Tšebeliso e tla ba 200-300 g, ka ho 1:, e omisitsoeng ke nako ea 60-90 metsotso.

Ho ea ka litaelo, ha li nooa li-slabs tsa rabara tse tsamaisang seterateng, khethollo e nyane e lokela ho etsoa (hoo e ka bang 2%) bakeng sa phallo ea mahala e ntseng e eketseha. Mesebetsi e etsoa feela nakong ea ho futhumala, ha mocheso o haufi o le 10 ... + 20 ea C.

Matšoao a mongobo ha a lokela ho feta 70%. Ho beha lithaele ho lumelloa feela ka setsing se ommeng.

Tekanyo ea mebuotsoana ea bokaholimo e ikemiselitse ho sebelisa letsoai le bonolo la ho jella le ho koaheloa ke sekepe sa konkreite 'me se koaheloa ka seketsoana sa khalase (banka, khalase, jj.). Haeba ka mor'a matsatsi a mabeli letsoai le ke ke la qhala 'me le lule le omitiloe, joale o ka qala ho tsitsa.

Likarolo tsa rabara tse koahelang konkreite li tšoaroa ka liketso tse latelang:

- Bohlale kapa bo-rabali-bina-bitumen bo sebelisoa hodimo e lokiselitsoeng ka botlalo le e fokolang (karolo e nyane), ebe sebopeho se hlahisoa ka mokhoa o felisitsoeng ka mokhoa o tšoanang ka sefofane sa mela. Ho sebelisa mofuta o ka bang phepelo ea khariso - 200-250 g, ka 1 m².

- Ho ea hōlang thao. Lintho tse ling tsa e mong li uetsa ka thata (ntle le likheo).

- Tile e 'ngoe le e' ngoe e hatelloa ka matla ho ea konkreite, bokaholimo bo fafatsoa ka coloic ho tlosa tlokotsi le ho tlosa moea.

- Sekhomaretsi se ileng sa oela ka lehlakoreng le ka pele ho tlosoa ka seponche hang-hang. Ho seng joalo, matheba a mabe a tla lula a le teng.

- Moeli o kentsoe haufi le sethala se khethiloeng.

- Kamora matsatsi a 2-3, sekhomakhabele se entsoe ka mokhoa o hlakileng, 'me ho tšoarolla liaparo tsa rabara ka ntle ho ka sebelisoa.

Sengoloa ka sehlooho: Mokhabiso oa lebota ka matsoho a hae: ho tobana le crate

Kamoreng

Tšebeliso ea lithaba tsa rabara e ratoa haholo joaloka setulo ka kichineng, ka kamoreng ea ho hlapela le meahong e meng ea bolulo.

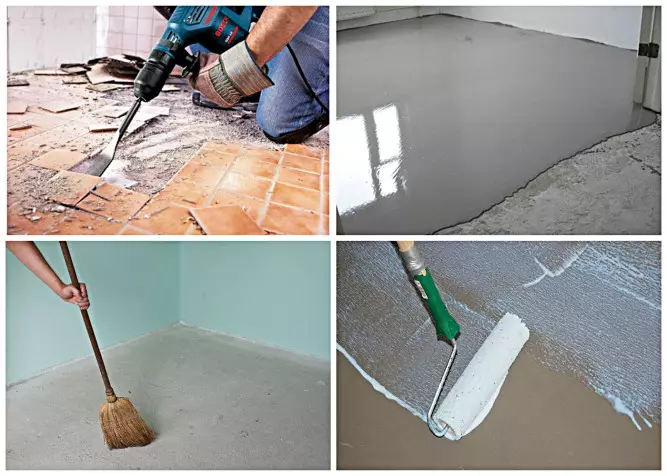

Qalong, motheo o lokiselitsoe ka hloko:

- Mokatong oa khale o tlosoa;

- Bokaholimo bo hlophisitsoe hape, haeba ho hlokahala);

- omisitsoe le ho hloekisoa ho tsoa lerōleng hantle ka sesepa sa vacuum;

- Fatše.

Ho kenya lithaelese tsa rabara ho etsoa ho tloha sebakeng se bohareng sa kamore. Bakeng sa sena, roulette e lekantsoe mme e etsoa ka mela e 2 ea perpendicular mela e tsoang hodimo e tsoang ho suren mabone a ka thoko ea kamore. Ho tloha sebakeng sa mats'oao a mela eo ba qala ho e beha. Metsoako ea Moruro e kenngoe ka mela e nang le tsoekere ho tloha. Ho khothalletsoa pele feela ho bolaoa ke boitsebiso bo kuta mokatong ntle le ho sebelisa glue.

Motsoako oa khomaretso o sebelisoa sebakeng se felisitsoeng ka sfatula kapa brashe e pharaletseng le ho emisa nako e itseng (e bontšitsoeng ka litaelo). Sekhomaretsi se koahetsoe le lehlakore le fosahetseng la thao. Ebuti e behiloe sebakeng se nepahetseng, e hatelloa ka matla ho ea motheong mme e khahliloe ke setšoantšo. Mojule o haufi o beoa ka tsela e ts'oanang 'me o kopantsoe ke li-bushing kapa k'homphieutha.

Tlas'a likarolo tsa rabara ha lia lokela ho hiroa libaka le li-bubble tsa moea. Lihlahisoa li behiloe, bophara bo lumellanang le sekoti se setseng eseng ho feta 1.5 mm.

Ho bohlokoa ho tsamaea ka thepa e ngata kamoo ho ka khonehang ho lahla lithaelese. Kamora ho omisa karolo e khokhothelang ka lihora tse 12 ho isa ho 48), rabara ea rabara e ka sebetsa ka bolokolohi. Ho thusa nako ea glue ka kotloloho ho latela matšoao a mocheso le mongobo ka phapusing.

Tlhokomelo le ho hlatsoa liaparo

Tile e loants'oa ho khatello ea mocheso le lintlha tse fapaneng tsa boemo ba leholimo, kahoo ha ho na mathata a khethehileng ho hlokomela kobo ea rabara.Ka lebaka la thepa e ntle ea 'mele, thepa ena ha e makatsoe ke likolone tse futsanehileng le tse bobupa ebile li se tsa senyeha ke litoeba.

Tšilafalo e bobebe e hlatsoa metsi ka metsi hose. Litšila le li-stains li itlotsa ka borashe ka sesepa kapa eng. Tšabo, lehlabathe, lesela le oeleng le lipekere tse nyane tsa perekisi li fifatsa lefielo kapa pan. Haeba u lakatsa, u ka sebelisa sets'oants'o sa decuum ea kaho. Lehloa le lehloa li hloekisitsoe mariha li hloekisitsoe ka kharafu (polasetiki kapa lepolanka). Lisebelisoa tsa tšepe li ne li sa lokela ho sebelisoa, kaha li ka senya bokaholimo ba li-le ho feta.

Ho Fokotsa Thaba ea rabara

Fokotsa beche ea rabara e thoeng ka motheong oa lefatše e bonolo haholo. Ho etsa sena, nahana feela le ho khaola lithaelese. Ebe u tsamaisa lintho 'me u behe sebakeng se seng. Li-module tse sephara ha li khothalletsoe, kaha ho ka senyeha ha ho ka senyeha mosebetsi. Ka linako tse ling thepa e tepelletseng e kopantsoe le tahlehelo e fokolang.