Isithando somlilo senzelwe ukuhogela insimbi yensimbi.

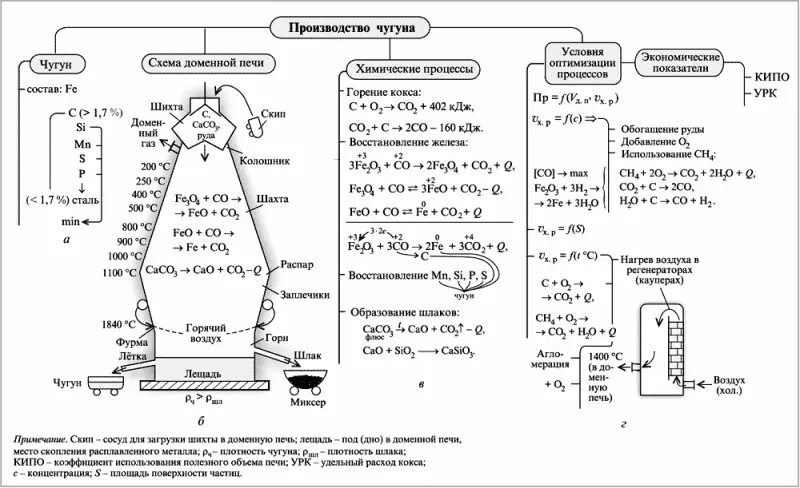

Umdwebo Wenqubo Yesizinda.

Umnyombo wale nqubo ukuthi isithando somlilo sibuyiselwe yi-Iron Oxides, esezintweni zomthombo - Imikhiqizo ye-Ore, Imikhiqizo yokuvuselelwa kwamafutha - I-Hydrogen, Carbon oxide nekhabhoni eqinile. Idivaysi yohlobo lwe-shaft blast aluyonankimbi enkulu yobunzima obukhulu. Siqukethe imininingwane eminingana.

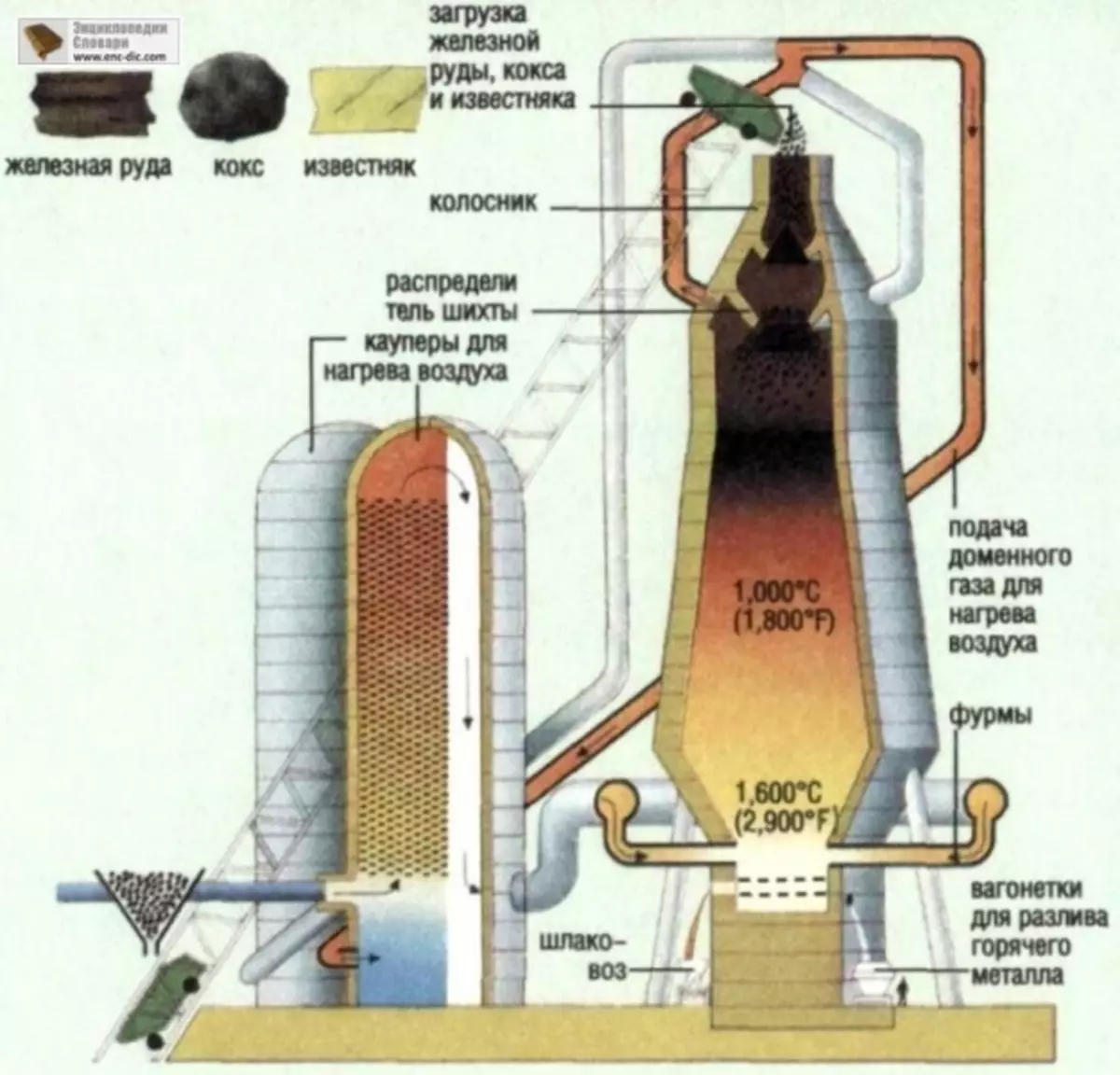

Idizayini yesithando somlilo

Ingxenye engenhla yesithando somlilo ibizwa ngokuthi yi-cosser. Ifakwe ama-feeders kagesi akhonza ukususa i-cozer gase. Lokhu kulayishwe ngezinto eziluhlaza ngokusebenzisa izinto ezikhethekile eziwayo.Ngaphansi kwe-colruslo kukhona amayini ane-cone eshiyelwe, andisa incwadi. Leli fomu lenza kube lula ukwenza lula inqubo yokutholwa kwezinto ezingavuthiwe ezivela ePokrovnik. Emayini, izinto zokuqala ezingavuthiwe ezivela ku-ore oxides zibuyiselwa ngensimbi zilungiselelwe ngendlela ekhethekile.

Ingxenye ebanzi kakhulu yesithando somlilo ibizwa ngokuthi yi-rake. Uhlobo olungenalutho lweFlux kanye no-Ore luyesa lapha, ngenxa yokuthi i-slag itholakala khona.

Ingxenye elandelayo yesithando somlilo iyisigaxa esincishisiwe esandayo. Ibizwa ngokuthi ama-pader. Kulomklamo, ukwakheka kwe-slag kuyaphela, kushiye amanye ama-flux kanye nophethiloli oqinile kukho.

Ukuhlanganiswa kukaphethiloli okutholwe ngaphezulu kwenzeka entabeni. Kuphinde kube nokukhonza ukuqongelela i-iron ne-slag, esesimweni se-liquid.

Ukushisa uphethiloli, kudingeka umoya oshisayo. Ingena esithandweni somlilo kusuka ekushiseni komoya ngokusebenzisa i-duct yonyaka, edlula kwi-tunts. Ngaphansi kwentaba, okuyigama le-lush, lisesisekelweni esikhulu kusuka kukhonkolo oqinisiwe. I-slag ne-cast iron iqoqwa lapha. Ekupheleni kwenqubo yokunyica, i-Iron Iron kanye ne-SLAG iyatholakala ezimibheni ezikhethekile kulowo abashayeli bezindiza ezihloselwe lokhu, emabhakede.

Umgomo wesithando somlilo

Isikimu se-Dominal Funeme.

Idizayini yesithando somlilo ihlelwe ngendlela yokuthi ingxube ingena esitsheni ngokusebenzisa idivaysi ewayo, yenziwe ngesigaxa esincane esisephezulu. Okulandelayo, kusuka endishini, kuwele isigaxa esikhulu lapho kuyacisha, icala lingena kuhhavini. Uhlelo olunjalo aluvumeli igesi kusuka esithandweni sokuqhuma ukuze ungene endaweni. Ngemuva kokulayisha, isigaxa esincane kanye ne-funnel yokuthola izinto ezingavuthiwe zijikeleza nge-angle, ama-degree amaningana. Lokhu kuyadingeka ukuze ingxube ihanjiswe ngokufanayo.

Isihloko ngesihloko: Ukulungiswa endlini yokugezela okuhlangene nendlu yangasese: Ukufundiswa kwesithombe

I-oven ye-metallurgical iyaqhubeka nokusebenza, ingxube incibilikisiwe futhi yehlela phansi, ikhulula indawo yezingxenye ezintsha zezinto zokusetshenziswa. Ivolumu ewusizo yesizinda kufanele ihlale igcwaliswe ngokuphelele. Isithasiselo sesizinda sanamuhla singaba nevolumu ewusizo kusuka ngo-2000 kuye ku-50 ³. Ukuphakama kwaso kungafinyelela kuma-35 m, cishe amaphindwe kathathu ngobubanzi bawo. Idizayini enjalo yenziwa ngaphandle kokwehluleka: Umgomo wesithando somlilo ususelwa ekuhambeni kwezinto zokwakha namagesi abheke komunye nomunye, okuvumela ukwandisa ukusetshenziswa kokushisa ku-85%.

Uphondo noLeshech benziwa ezitini ezinamabhulokhi enkulu noma amabhlogo wekhabhoni. Zitholakala ngaphakathi kwe-casing yensimbi futhi njalo ekusebenzeni kokusebenza zipholile ngamanzi aza nezinhlelo ezimbili zamanzi ukusuka eziqandisini zomklamo okhethekile. Futhi lapho uhlelo lokuqala lusebenza, owesibili ngalesi sikhathi usesendaweni yokugcina. I-Movers, Shaft kanye ne-Rake yenziwa ngezitini ezihlanjiwe.

IPischarik ihlotshiswe ngamapuleti ensimbi, i-cavity ngaphakathi egcwaliswa ngokuphelele ngeShamoti, ne-dome yesithando somlilo - izitofu zivela e-cast iron.

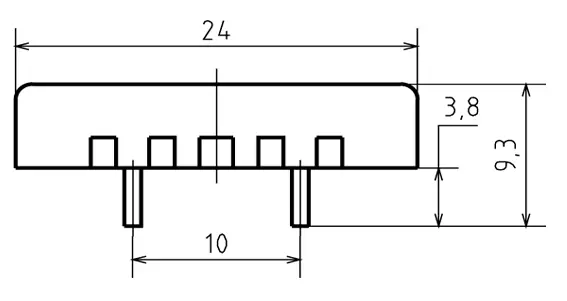

Izindatshana Ezingeziwe Zesizinda Sesizinda

Umdwebo wedivaysi yesithando sesizinda.

Enqubweni yomsebenzi kudinga amadivaysi asizayo nezinqubo ezinikezela ukuncibilika kwensimbi esezingeni eliphakeme. Siyadingeka ngamadivayisi wokuphakamisa nokulayisha izinto zokuqala ezivuthiwe esithandweni somlilo.

Isithando somfaki wesizinda sidinga insizakalo yaphakade, ikakhulukazi lapho kukhishwa i-slag nensimbi. Kulokhu, kwasungulwa, okufakwe ama-cranes ebhuloho kuguqulwa. Ukushisa komoya kokusebenza komthamo, izinga lokushisa eliphakeme lokuncibilika ngenani elincane lomoya linikeza ama-heater air. Isibonelo, esithandweni somthamo owusizo ka-2000 m³, imishini enjalo kumele ihanjiswe ngomzuzu ngamunye womoya ongu-3,800 m³, izinga lokushisa lawo lingama-degree angama-1200. Imibhangqwana yakhiwa ngenxa yokugeleza komoya ku-Air heater kufanele isheshe ishele. Inani lale nkomba liyalungiswa kusetshenziswa uhlelo oluzenzakalelayo.

Umoya ocindezelwe, okudingekayo ukuze uvuse uphethiloli, ungena kuhhavini ngenxa yemishini yokushaya. Ingcindezi yayo ku-Asteres emagumbini wanamuhla ifinyelela ku-25 MPA. Ukuhlanzwa kwegesi Cozer kwenzeka ngokusebenzisa isiphepho segesi.

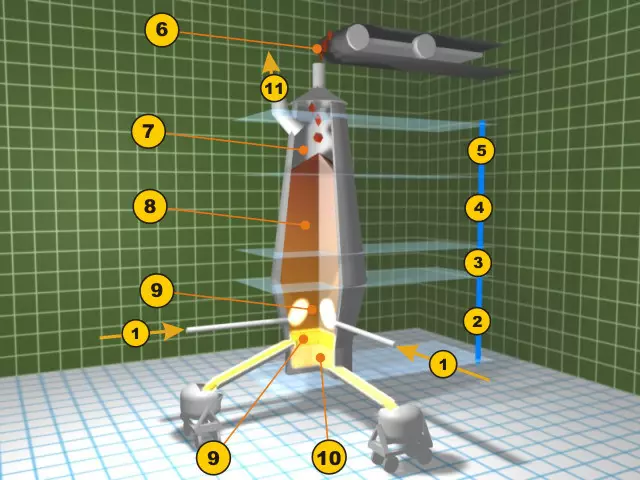

Yini inqubo yesizinda

Idivathosikinikazi yesithando sesizinda: 1. Ukushaya okushisayo.2. Ukuncibilika zone (pader kanye nophondo) .3. Indawo yokubuyisa i-feoo (i-rake) .4. Ukululama i-sone FE2O3 (eyami) .5. Indawo yokuhlanza (umugqa) .6 .6. Kulayishwa izinto zensimbi ze-Iron Ore, i-limestone ne-coke.7. Domain Gaza.8. Namanje wezinto zo-iron ore, i-limestone ne-coke.9. Khipha i-slag.10. Ukukhishwa kwe-liquid castron iron.11. Qoqa amagesi kadoti.

Isihloko ngesihloko: Amathrekhi weSandstone azenzela wena

Ukuze uthole ukunyibilika okuphumelelayo kwe-iron iron esithandweni sokuqhuma, okuvelele kumele kubhekwe ngaso sonke isikhathi. Okokuqala, amazinga okushisa kuwo wonke ama-oveni nokushisa kufanele aqinisekise ukugeleza kokuphendula okudingekayo endaweni efanele futhi ngesikhathi esithile. Lokhu kwenzeka ngenxa yenhlangano ebheke komunye nomunye imifudlana emibili. Igesi kusuka ekuvukeni kwamafutha isuka ezansi phezulu phezulu, kanye nengxubevange, ukushisa okufudumele kwegesi, yehla kusuka phezulu kuya phansi. Okwesibili, i-slag kufanele yakhelwe kuphela uma ukubuyiselwa kwensimbi kanye nokungcola okudingekayo okuvela ku-ore kuzophela. Kubalulekile ukukhetha kahle ukugcwaliswa kwe-slag nge-cast iron. Lokhu kuyadingeka ukuze i-slag ichitheke ngaphambi kwesikhathi i-ore, okuzoholela ekushintsheni kwendlela yokwakhiwa kwe-iron yensimbi futhi kungadala ukwehluleka kwinqubo yokubhema.

Ukuqala kwale nqubo ukushiswa uphethiloli. Lapho uxhumana nomoya-mpilo, igesi yemvelo kanye ne-carbon coke yokulwa, kwakha ukukhishwa okubalulekile kokushisa.

C + O2 = CO2 + Q; CH4 + 2O2 = CO2 + 2H2O + q

Ukuxhumana kwemikhiqizo yokuvutha nge-coke ngokuya ngokuphendula kwenzeka:

CO2 + C = 2CO - Q; H2O + C = CO + H2 - Q

Kule ngxube, i-carbon monoxide yi-ejenti eyinhloko enciphisa i-ejenti ye-iron oxides. Ukuze wandise ukusebenza komlilo, umoya ongena esithandweni siyanyiswa, ngenxa yokuthi inani lokunciphisa i-agent likhuphuka. Lapho uphakamisa i-gase, amazinga okushisa aphezulu anele ngokwanele, afudumeza ingxube. Bona uqobo bapholile cishe ngama-300-400 degrees. Ingxube ihamba phansi ukuze ihlangabezane negesi. Lapho amazinga okushisa efinyelela cishe ngo-570 ° C, ama-oxide we-iron axide abuyiselwa. Le nqubo iqukethe izigaba eziningana ezilandelanayo Ngokusho kwesikimu: FE2O3 -> FEO4 -> Feo -> Fe.

Lokhu kusabela kwamakhemikhali kunquma izinga lokushisa. Ukubuyiselwa kwe-Iron Oxide kwenzeka nge-carbon eqinile (ukuncishiswa okuqondile), i-hydrogen kanye ne-carbon oxide (ukululama okungaqondile). Esimweni sokuqala, inqubo yenziwa endaweni yokukhipha uma kunamazinga okushisa aphezulu ngokuya ngokusabela: FEO + C = FE + CO - Q.

Esimweni sesibili, ngokuncishiswa okungaqondile, ukusabela kwenzeka emazingeni okushisa aphansi ngaphezulu kwesithando: 3fe2o3 + co = 2fe3o4 + CO2 + Q; Fe3o4 + co = 3fe O + CO2 - Q; FE O + CO = FE + CO2 + Q.

Isihloko ngesihloko: Ungasika kanjani indlu ye-log e-paw?

Ukwakheka kwe-shag

Ekushiseni okudingekayo kwensimbi, kuncishiswe kusuka ku-ore, ngokuphendula okuthile kuncibilika ikhabhoni. Ngenxa yalokhu, kunokuncipha endaweni yokuncibilika, futhi insimbi incibilike ekushiseni okungaba ngu-1300 ° C C. I-alloy ephumela, ukuxhumana ne-coke, igcwele izakhi njenge-silico, phosphorus, ikhabhoni, i-manganese, yatholakala ku-ore. Ukugcwaliswa kweSulfur kwenzeka ekushiseni kwama-degree angama-1200 ukusuka eCoke. Ngezansi kwesithando somlilo lapho kufakwa ama-fluxes, idwala elingenalutho kanye ne-ash ukuzalanisa kwe-slag kuqukethe ukwakheka kwezinkohliso zezinto ezifanayo ne-alloy. Ukwakheka kwe-slag, kanye ne-iron cast, kunqunywa ukwakheka kwengxube yokuqala. Ngenxa yokuthi i-slag inobunzima obuncane, itholakala ebusweni bensimbi elahlekile.

I-Iron Engalungile Yesikulungele ikhiqizwa kusuka esithandweni somlilo ngeflaya njalo emahoreni ama-3-4. I-SLAG nayo ikhiqizwa komunye umshayeli wendiza ngemuva kwamahora angama-1-2. Abashayeli bezindiza bavulwa ngedivaysi ekhethekile, bese bevalwa ngokwakheka okusebenzayo. I-Iron ne-Slag ihlangana ngamabhakede akhethekile nasezitsheni. Okulandelayo, i-cast iron ithunyelwa esitolo - uMartenovsky noma i-oxygen Converter, - lapho kuqhubeka khona ukucutshungulwa kwalo.

Imikhiqizo ebibangelwa inqubo yesizinda

Umkhiqizo obaluleke kakhulu ovela ekunyisweni yi-Iron Iron, okuyizinhlobo ezahlukene - amalungelo ahlukahlukene kanye nama-Alleights. Banokuqukethwe okuhlukile kwezakhi, kuya ngokuthi ukusetshenziswa kwawo okwengeziwe kwenzeka nini.

Kanye nomkhiqizo oyinhloko lapho uluka, imikhiqizo eyengeziwe iyatholakala - i-slag, igesi cosserniki uthuli. I-SLAG isetshenziselwa ukwenza izinto zokwakha. Isibonelo, uma kuthulula emanzini, kutholakala impahla enesakhiwo esihle esihle. Isetshenziselwa kamuva ukukhiqizwa kwezitini, usimende nezinye izinto.

Kwakhiwa igesi ye-palcetic lapho ukuhlanganiswa kwamafutha kuhlanzwa ngendlela ekhethekile kusuka othulini nasezinhlakenili ze-ore. Isetshenziswa njengophethiloli ematholeni domain kanye nama-boilers asebenza emanzini noma umbhangqwana. Uma uxuba igesi ebanzi nemvelo, khona-ke ingasetshenziswa eMarthen izinyanga.

Omunye umkhiqizo wesizinda Swengung uthuli oludala. Kuqukethe ukwakheka kwalo kusuka ku-40 kuye ku-50% yensimbi futhi kusetshenziswa kabanzi e-agglomeration.